Spree

Dedicated LVC Member

Thank's to:

DLF

http://www.lincolnvscadillac.com/showthread.php?t=77865

slowmarkviii

http://www.lincolnvscadillac.com/showthread.php?t=74935

and

http://www.lincolnvscadillac.com/showthread.php?t=46645

For the torque specs.

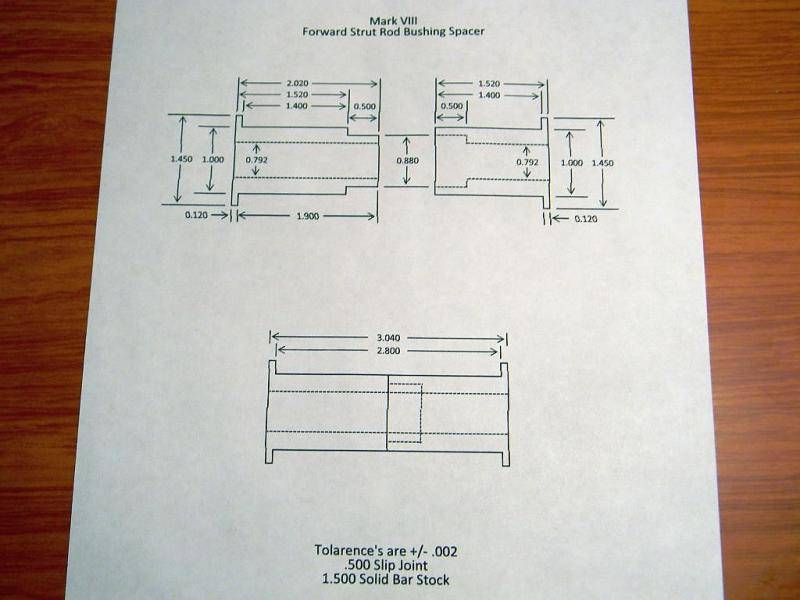

For there detailed thread's on the forward SRB spacer and torque specs. This is what I came up with. Going to work tomorrow (on my day off) to play with the CNC and hopefully the spacer's come home with me. Going to make this out of a 1.5" solid bar so there is no welding.

SRB's are here and look great!

1" drill bit to re-drill stock forward SRB washer to accept new spacer.

Had to buy a bigger torque wrench (needed it anyway).

Lower Control Arm's will be here middle of next week.

Deep well high impact socket set up to 32MM will be here middle of next week (love buying tool's).

I can't seem to find a thread on replacing any of these on LVC or Google so maybe this will be it!

Anything else I need to know before attempting this?

Shut air ride off.

Remove air spring (just so I don't damage it).

Remove caliper (hang out of the way).

Remove wheel speed sensor?

Remove lower ball joint.

Mark cam bolt so I can put it back to the original location as close as possible.

Remove cam bolt.

Remove LCA to SRB nut.

Remove LCA to frame nut.

Don't have to remove tie rod end (is this true)? Swing spindle out of the way.

Replace all the bad crap and re-assemble.

Maybe not in this order, did I miss anything?

DLF

http://www.lincolnvscadillac.com/showthread.php?t=77865

slowmarkviii

http://www.lincolnvscadillac.com/showthread.php?t=74935

and

http://www.lincolnvscadillac.com/showthread.php?t=46645

For the torque specs.

For there detailed thread's on the forward SRB spacer and torque specs. This is what I came up with. Going to work tomorrow (on my day off) to play with the CNC and hopefully the spacer's come home with me. Going to make this out of a 1.5" solid bar so there is no welding.

SRB's are here and look great!

1" drill bit to re-drill stock forward SRB washer to accept new spacer.

Had to buy a bigger torque wrench (needed it anyway).

Lower Control Arm's will be here middle of next week.

Deep well high impact socket set up to 32MM will be here middle of next week (love buying tool's).

I can't seem to find a thread on replacing any of these on LVC or Google so maybe this will be it!

Anything else I need to know before attempting this?

Shut air ride off.

Remove air spring (just so I don't damage it).

Remove caliper (hang out of the way).

Remove wheel speed sensor?

Remove lower ball joint.

Mark cam bolt so I can put it back to the original location as close as possible.

Remove cam bolt.

Remove LCA to SRB nut.

Remove LCA to frame nut.

Don't have to remove tie rod end (is this true)? Swing spindle out of the way.

Replace all the bad crap and re-assemble.

Maybe not in this order, did I miss anything?