Right on the Mark

Dedicated LVC Member

Now I'm going to start off by saying the mods done to rims are the least evasive as I could get. I am cheap and needed 17 or larger rims to clear the front cobra rotors. I wanted 17's so I could find nice cheap tires. I found a set of 99 GT rims and tires for 100 bucks. Here they are on the car.

Ok I'm going to have to make a disclaimer here because this is my car and I work on it how I please. This write up does not imply that this is the only way to do this or the best way.Just way I did it. That said,on we go.

The plan was to get the rims on the car for 0 money. No hub change. I didn't want to remove the hubs and redrill pattern. So that left notching rims to fit. I didn't want to dismount the rims and tires to fit on Bridgeport so that meant a drill fixture on rim.

Here is the fixture with .625 dowels and .500 endmill cutter or notcher.On this side you just see the Mk8 Bolt circle (BC) that is what will be transfered to the rims.

Here is other side you can see the (3) counter sunk .625 holes that are the Mustang BC. These .625 dowels lock the fixture in 100% correct spot for the notching and such.

First step is to hand reamer the rims to make the holes .6255 so dowels will just slip in. The rims holes are .623 so pins wouldn't go in.

Next step is clamp fixture on while using the (3) dowels to align it.Then chuck up special endmill I made to notch .500 dia in rims.

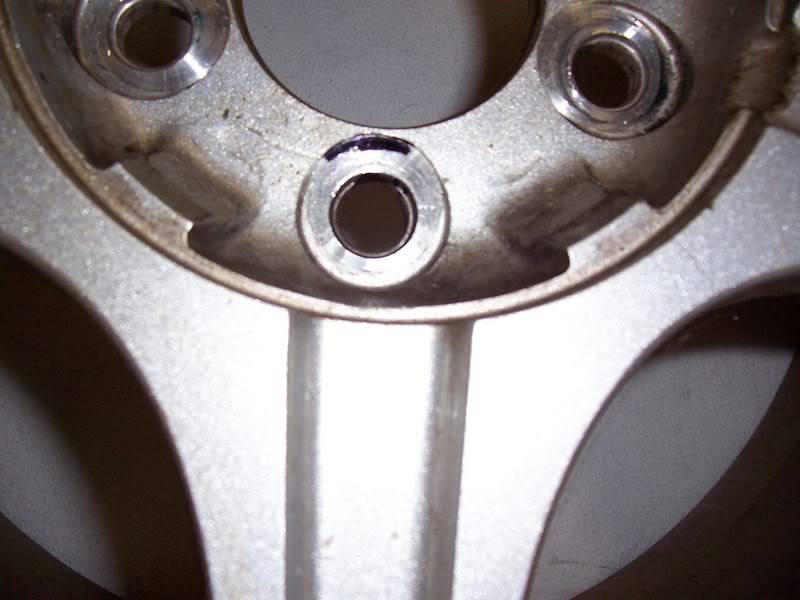

With that done I now needed a larger dia. then normal lugnut to clamp on complete rim surface. I found perfect lugs from a 2000 Lincoln LS.Here is fitment of lugs to rims.

First lugs need to be cut flat. In this pic you see stock lug with nipple I removed that and made them flat.Ford does lugs this way on there trucks.

Now lug was too big dia and didn't fit into the brow cutout of rim. So need to notch the brows. I made this tool to notch brows.

Here is area needing to be removed in black.

Here is the cutter in postion chuck it up in a drill and notch.

Now here is all on car and also my track won't let you race with snap on hubcaps unless there positivly secured. So I made fixture that will let me drill right down center of the stud and tap that for screw to hold hubcaps on 100%

Here are the spacers needed to not pull cap in too much with the bolt poking thru.

I forgot to ad that all 4 rims need hub rings so I whipped up 4. Here they are.

And thats how I got my rims on for 32 dollars for LS lug nuts.

Ok I'm going to have to make a disclaimer here because this is my car and I work on it how I please. This write up does not imply that this is the only way to do this or the best way.Just way I did it. That said,on we go.

The plan was to get the rims on the car for 0 money. No hub change. I didn't want to remove the hubs and redrill pattern. So that left notching rims to fit. I didn't want to dismount the rims and tires to fit on Bridgeport so that meant a drill fixture on rim.

Here is the fixture with .625 dowels and .500 endmill cutter or notcher.On this side you just see the Mk8 Bolt circle (BC) that is what will be transfered to the rims.

Here is other side you can see the (3) counter sunk .625 holes that are the Mustang BC. These .625 dowels lock the fixture in 100% correct spot for the notching and such.

First step is to hand reamer the rims to make the holes .6255 so dowels will just slip in. The rims holes are .623 so pins wouldn't go in.

Next step is clamp fixture on while using the (3) dowels to align it.Then chuck up special endmill I made to notch .500 dia in rims.

With that done I now needed a larger dia. then normal lugnut to clamp on complete rim surface. I found perfect lugs from a 2000 Lincoln LS.Here is fitment of lugs to rims.

First lugs need to be cut flat. In this pic you see stock lug with nipple I removed that and made them flat.Ford does lugs this way on there trucks.

Now lug was too big dia and didn't fit into the brow cutout of rim. So need to notch the brows. I made this tool to notch brows.

Here is area needing to be removed in black.

Here is the cutter in postion chuck it up in a drill and notch.

Now here is all on car and also my track won't let you race with snap on hubcaps unless there positivly secured. So I made fixture that will let me drill right down center of the stud and tap that for screw to hold hubcaps on 100%

Here are the spacers needed to not pull cap in too much with the bolt poking thru.

I forgot to ad that all 4 rims need hub rings so I whipped up 4. Here they are.

And thats how I got my rims on for 32 dollars for LS lug nuts.