DLF

Dedicated LVC Member

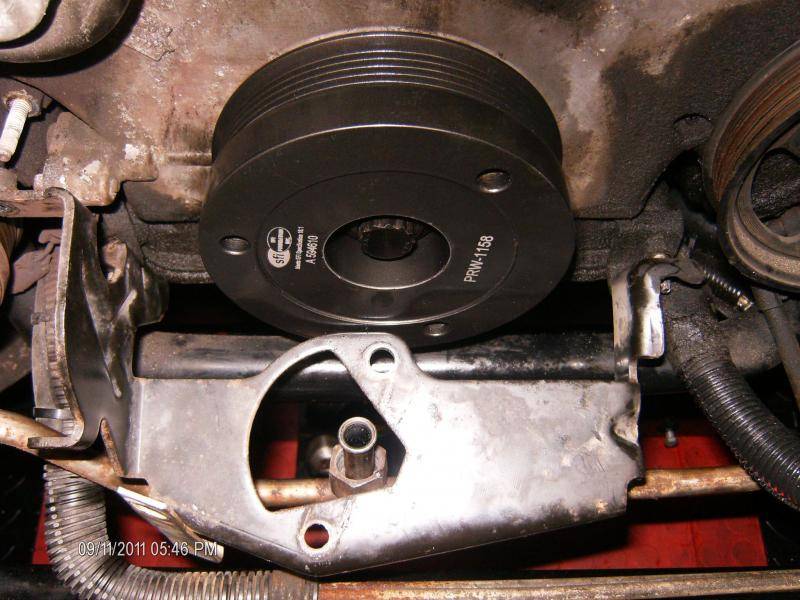

Has anyone installed UD pulleys on a Gen 2 and retained the Secondary Air Injection Diverter Valve?

It won't fit without modification as the front of the March balancer is solid.

Also, does anyone have a diverter valve for sale? If I decide to keep it, I'm going to need a new one, this one was really stuck, and the threads are gone now.

BTW - Not my car.

It won't fit without modification as the front of the March balancer is solid.

Also, does anyone have a diverter valve for sale? If I decide to keep it, I'm going to need a new one, this one was really stuck, and the threads are gone now.

BTW - Not my car.