My '94 has gone through some changes since I purchased her back in 2002. A 9 year gap until I joined LvC.

I'd like to share with you some of the photos of what I have done in the past and culminate with the current overhaul. Like with every other projects, it may never be completely done. If you are like me, you know what I mean.

.

.

.

.

.

.

So, here we go.... The first thing I needed to do was to make her look purdy again after being mistreated by the previous owner. As you can see, she cleaned up real nice in the picture above. Next, I wanted a nice soundsystem that looks completely factory looking. I've always thought that the Mark's sound system was very good but I had some ideas to make it sound even better. What better way to prove it than to go and compete head to head with some of the best sound competitors out there with their expensive lists of equipment and sponsorships.

Fast-forward a little bit: Using mostly stock audio equipment in my Mark, I was able to take home one of these after its very first time competing at a soundoff competition. There were a few competitors in my class that were pissed and couldn't believe they were beat by a car with only a factory system. Even I couldn't believe it took 1st.

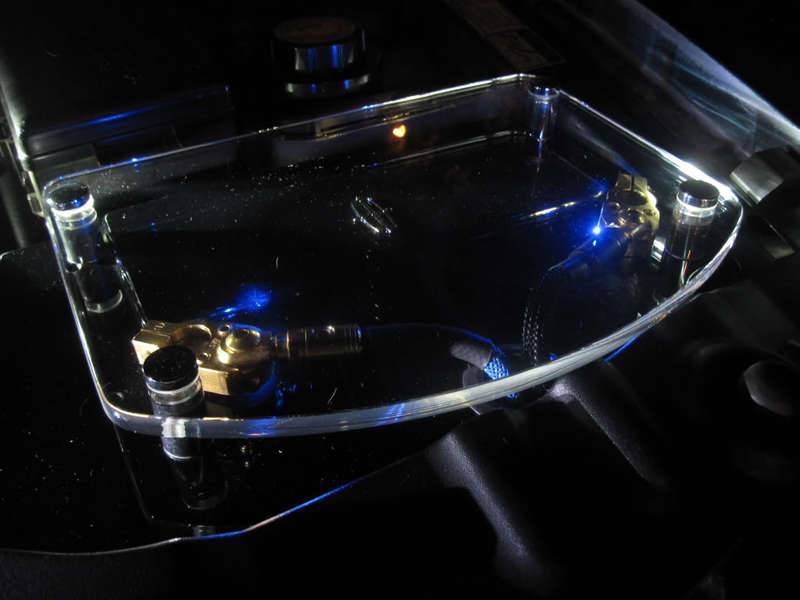

But here's the difference. The system is really not completely factory but I chopped and cut a few things to make it sound better and made sure the interior looked factory to everyone else. Under the engine bay, it has a blue LED lit plexiglass battery cover (as some of you may remember).

From the battery, I ran two 4 gauge Streetwires power cables that were fused with a 50A wafer at the battery post. The other is the ground wire connected to the alternators case. All my wires are terminated with Streetwires hardware.

.

.

.

.

.

.

.

.

.

.

Both cables are covered with expanding mesh and split loom. I wrapped the cables with 3M electrical tape to further keep the factory look throughout the installation. The rubber grommets are the factory ones from the Driver side door post. Holes were made on each grommet that are slightly smaller than the wires diameter ensuring a snug fit to prevent water from entering the car.

.

.

.

.

The wires were routed under the left fender well as opposed to running them inside the engine bay. The benefits to routing wires this way is to avoid EMI within the engine bay, avoids extreme heat against the exhaust headers and it is a straight run from the battery to the cabin entry holes behind the drivers side door hinges.

.

.

.

.

Aircraft style wire mount harness were used to keep the wires from being damaged by chaffing and vibration. Close spacing on the mounting harness means that these wires will not sag. Once the plastic wheel well cover is back on, no one would ever suspect anything was ever done in that area.

.

.

.

.

.

.

.

.

.

.

The wires were routed along the side of the floorboard into the trunk and connects to a Streetwires ground block and a fused distribution block. Those photos were lost when my computer crashed. They will be providing power for these.

.

.

.

.

The amp is an old school 200 watt Linear Power 2002. This is still one of the finest small and powerful amps ever built. It will be supported by a Streetwires 1 farad capacitor to keep those transients in check. It will be driving a pair of Rockford Fosgate PCH-124 12" subwoofers.

.

.

What good are they without a box you ask? No worries. I contacted RF's technical department to get the parameters needed to build the box to spec. These subs perform best in a tuned-ported enclosure so I gathered all the necessary parts, took all the measurements and started cutting. The enclosure is made of eleven ply birch plywood and sealed with clear urethane varnish.

.

.

.

.

.

.

.

.

Before mounting the speakers in place, I generously placed one pound of wool batting in the enclosure to control and tame the resonance in the box. And with the common/multi-chamber design, bass sounds cleaner, tighter and less boomy.

.

.

.

.

.

.

.

.

The small cavity you see on the back of the box is where the amp and capacitor will be mounted. Because it is such a small area, it is really not an ideal place to put an amplifier. Amplifiers need cool air circulation to operate at its optimum and keep it from shutting down or worse, burning up especially since I am going to cover the back of the box with a detachable beauty trim. In order to keep the amp from overheating, the amp cavity area will be force cooled by a high flow fan that is triggered to come on when it senses power coming from the factory radio.

.

.

.

.

.

.

.

.

When viewing the back of the box, I did not want anyone to see a vent hole for the amp cooling fan so I made an air duct to hide the fan and to channel fresh air through the fan. I chopped a PVC tube in half and made a half dome out of plastic body filler. An old tennis ball came in handy as my mold. I finished it off by sanding the dome to perfectly blend in with the contour of the air duct. I was lucky enough to find a trunk carpet material that perfectly matches the carpet in the Mark. Once the box was installed, and secured in the trunk, all you would appear to see is a large empty trunk space without a hint of a sub box and an amp.

.

.

.

.

.

.

.

.

Next on the to do list is the center channel speaker pod. It will be making its home where the control buttons are for the message center. A new extension harness is made to allow the buttons to be relocated adjacent to the dome light. The purpose for this mod is to better anchor the voices up and center of the front stage. The center speaker are driven by the factory JBL amp using a KEF center channel transformer.

.

.

.

.

.

.

.

.

Blue LEDs light up the back of the center message control buttons creating a cool halo effect. LEDs are bright enough to light the interior at night with a low moonlight glow in blue.

This pod will take up the same room as the control panel its replacing. The tweeter driver is the same as those on the doors but the 4" mid is an old Polk Audio I had laying around. I later replaced it with an Infinity 4" mid. The pod is made out of wood and plexiglass wrapped by simulated leather vinyl. The center speakers are protected with a metal mesh grille covered by black speaker cloth.

.

.

.

.

.

.

.

.

.

.

Holes were drilled out on the plexiglass and edges were polished to a glassy shine. The pod is shaped to drop right in at the opening and is secured to the dash using 6 screws that will be hidden under another layer of black plexiglass. Speaker cloth is wrapped around the grille with the excess trimmed off and its edges hidden by yet another layer of plexiglass.

.

.

.

.

.

.

Here, you see the speaker pod taking shape. All edges sanded smooth to give the vinyl wrap a real nice look with no surface imperfection.

.

.

.

.

.

.

.

.

Wires for the center speakers are soldered and shrink tube is used for better protection. The final product looking like it came from the factory.

.

.

.

.

.

.

.

.

A better view of the center speaker grille. A perforated metal grille is sandwiched between two plexiglass sheets. Bottom plexiglass trim is polished all around. Small rubber bump stops eliminates any viblration from making any unwanted rattles.

.

.

.

.

.

.

.

Speaker pod is dyed to match the dash color. Grill installed over the speakers.

.

.

Center speaker pod installed in the dash where the message center control buttons were.

.

.

To get a smooth balanced sound in the car, I am equalizing the signal using a PPI DEQ-230 stereo 30-band graphic equalizer.

The best place to tap for a line level signal is at the factory CD changer sound board. A stereo input and output signal connection is created by putting four RCA connection to the back of the changer case.

.

.

.

.

.

.

.

.

.

.

Once the signal is equalized, it is looped back to the CD changer audio board. Modification to the signal output stage was performed at the external modulation board. I needed to maintain the clean equalized line level signal to output at the modulator. There, you see where the red and white RCA pigtails comes out from the modulator. This is the area where the biggest improvement of sound quality comes from.

.

.

.

.

.

.

.

.

Since the sound system is now able to reproduce higher frequencies better, I am now able to bring the soundstage much higher at eye level. Added three more tweeters from Focal for the left, center and right channels. These are the T-53 inverted dome, titanium tweeters. Tweeter pods installed at both left and right A-pillars. Center tweeter is installed on the dash between the windshield defroster vents.

.

.

.

.

.

.

.

.

All modifications were done to improve the aesthetics and compliment the existing parts in the interior and make it look as factory as possible as if nothing was done to the vehicle. The front and rear factory speakers remained untouched.

-Ren

I'd like to share with you some of the photos of what I have done in the past and culminate with the current overhaul. Like with every other projects, it may never be completely done. If you are like me, you know what I mean.

So, here we go.... The first thing I needed to do was to make her look purdy again after being mistreated by the previous owner. As you can see, she cleaned up real nice in the picture above. Next, I wanted a nice soundsystem that looks completely factory looking. I've always thought that the Mark's sound system was very good but I had some ideas to make it sound even better. What better way to prove it than to go and compete head to head with some of the best sound competitors out there with their expensive lists of equipment and sponsorships.

Fast-forward a little bit: Using mostly stock audio equipment in my Mark, I was able to take home one of these after its very first time competing at a soundoff competition. There were a few competitors in my class that were pissed and couldn't believe they were beat by a car with only a factory system. Even I couldn't believe it took 1st.

But here's the difference. The system is really not completely factory but I chopped and cut a few things to make it sound better and made sure the interior looked factory to everyone else. Under the engine bay, it has a blue LED lit plexiglass battery cover (as some of you may remember).

From the battery, I ran two 4 gauge Streetwires power cables that were fused with a 50A wafer at the battery post. The other is the ground wire connected to the alternators case. All my wires are terminated with Streetwires hardware.

Both cables are covered with expanding mesh and split loom. I wrapped the cables with 3M electrical tape to further keep the factory look throughout the installation. The rubber grommets are the factory ones from the Driver side door post. Holes were made on each grommet that are slightly smaller than the wires diameter ensuring a snug fit to prevent water from entering the car.

The wires were routed under the left fender well as opposed to running them inside the engine bay. The benefits to routing wires this way is to avoid EMI within the engine bay, avoids extreme heat against the exhaust headers and it is a straight run from the battery to the cabin entry holes behind the drivers side door hinges.

Aircraft style wire mount harness were used to keep the wires from being damaged by chaffing and vibration. Close spacing on the mounting harness means that these wires will not sag. Once the plastic wheel well cover is back on, no one would ever suspect anything was ever done in that area.

The wires were routed along the side of the floorboard into the trunk and connects to a Streetwires ground block and a fused distribution block. Those photos were lost when my computer crashed. They will be providing power for these.

The amp is an old school 200 watt Linear Power 2002. This is still one of the finest small and powerful amps ever built. It will be supported by a Streetwires 1 farad capacitor to keep those transients in check. It will be driving a pair of Rockford Fosgate PCH-124 12" subwoofers.

What good are they without a box you ask? No worries. I contacted RF's technical department to get the parameters needed to build the box to spec. These subs perform best in a tuned-ported enclosure so I gathered all the necessary parts, took all the measurements and started cutting. The enclosure is made of eleven ply birch plywood and sealed with clear urethane varnish.

Before mounting the speakers in place, I generously placed one pound of wool batting in the enclosure to control and tame the resonance in the box. And with the common/multi-chamber design, bass sounds cleaner, tighter and less boomy.

The small cavity you see on the back of the box is where the amp and capacitor will be mounted. Because it is such a small area, it is really not an ideal place to put an amplifier. Amplifiers need cool air circulation to operate at its optimum and keep it from shutting down or worse, burning up especially since I am going to cover the back of the box with a detachable beauty trim. In order to keep the amp from overheating, the amp cavity area will be force cooled by a high flow fan that is triggered to come on when it senses power coming from the factory radio.

When viewing the back of the box, I did not want anyone to see a vent hole for the amp cooling fan so I made an air duct to hide the fan and to channel fresh air through the fan. I chopped a PVC tube in half and made a half dome out of plastic body filler. An old tennis ball came in handy as my mold. I finished it off by sanding the dome to perfectly blend in with the contour of the air duct. I was lucky enough to find a trunk carpet material that perfectly matches the carpet in the Mark. Once the box was installed, and secured in the trunk, all you would appear to see is a large empty trunk space without a hint of a sub box and an amp.

Next on the to do list is the center channel speaker pod. It will be making its home where the control buttons are for the message center. A new extension harness is made to allow the buttons to be relocated adjacent to the dome light. The purpose for this mod is to better anchor the voices up and center of the front stage. The center speaker are driven by the factory JBL amp using a KEF center channel transformer.

Blue LEDs light up the back of the center message control buttons creating a cool halo effect. LEDs are bright enough to light the interior at night with a low moonlight glow in blue.

This pod will take up the same room as the control panel its replacing. The tweeter driver is the same as those on the doors but the 4" mid is an old Polk Audio I had laying around. I later replaced it with an Infinity 4" mid. The pod is made out of wood and plexiglass wrapped by simulated leather vinyl. The center speakers are protected with a metal mesh grille covered by black speaker cloth.

Holes were drilled out on the plexiglass and edges were polished to a glassy shine. The pod is shaped to drop right in at the opening and is secured to the dash using 6 screws that will be hidden under another layer of black plexiglass. Speaker cloth is wrapped around the grille with the excess trimmed off and its edges hidden by yet another layer of plexiglass.

Here, you see the speaker pod taking shape. All edges sanded smooth to give the vinyl wrap a real nice look with no surface imperfection.

Wires for the center speakers are soldered and shrink tube is used for better protection. The final product looking like it came from the factory.

A better view of the center speaker grille. A perforated metal grille is sandwiched between two plexiglass sheets. Bottom plexiglass trim is polished all around. Small rubber bump stops eliminates any viblration from making any unwanted rattles.

.

Speaker pod is dyed to match the dash color. Grill installed over the speakers.

Center speaker pod installed in the dash where the message center control buttons were.

To get a smooth balanced sound in the car, I am equalizing the signal using a PPI DEQ-230 stereo 30-band graphic equalizer.

The best place to tap for a line level signal is at the factory CD changer sound board. A stereo input and output signal connection is created by putting four RCA connection to the back of the changer case.

Once the signal is equalized, it is looped back to the CD changer audio board. Modification to the signal output stage was performed at the external modulation board. I needed to maintain the clean equalized line level signal to output at the modulator. There, you see where the red and white RCA pigtails comes out from the modulator. This is the area where the biggest improvement of sound quality comes from.

Since the sound system is now able to reproduce higher frequencies better, I am now able to bring the soundstage much higher at eye level. Added three more tweeters from Focal for the left, center and right channels. These are the T-53 inverted dome, titanium tweeters. Tweeter pods installed at both left and right A-pillars. Center tweeter is installed on the dash between the windshield defroster vents.

All modifications were done to improve the aesthetics and compliment the existing parts in the interior and make it look as factory as possible as if nothing was done to the vehicle. The front and rear factory speakers remained untouched.

-Ren