You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

500+ HP rear Axles?

- Thread starter tijoe

- Start date

I remember reading your posts on the swap but I can't seem to find them now. Did you ever get the jag systems to work with the swap?

2000 S-type with blown engine...

Her are a couple images that show 3 different Inner plunging CV joints.

Left: 31 spline 2010 F150 - Axle has 37 splines (fits 8.8 Mark VIII LSD Diff.)

Middle: 28 spline 2002 S-type - Axle has 36 Splines (fits gen 1 8.8 Diff.)

Right: 2006 Lincoln LS - Axle has 35 splines, smallest ( Fits Gen 2 Diff)

From all the research I've done to date, the F150 inner hub appears to be the strongest. The S-type is a close second. - The 06 LS looks wimpy overall.

Left: 31 spline 2010 F150 - Axle has 37 splines (fits 8.8 Mark VIII LSD Diff.)

Middle: 28 spline 2002 S-type - Axle has 36 Splines (fits gen 1 8.8 Diff.)

Right: 2006 Lincoln LS - Axle has 35 splines, smallest ( Fits Gen 2 Diff)

From all the research I've done to date, the F150 inner hub appears to be the strongest. The S-type is a close second. - The 06 LS looks wimpy overall.

Last edited:

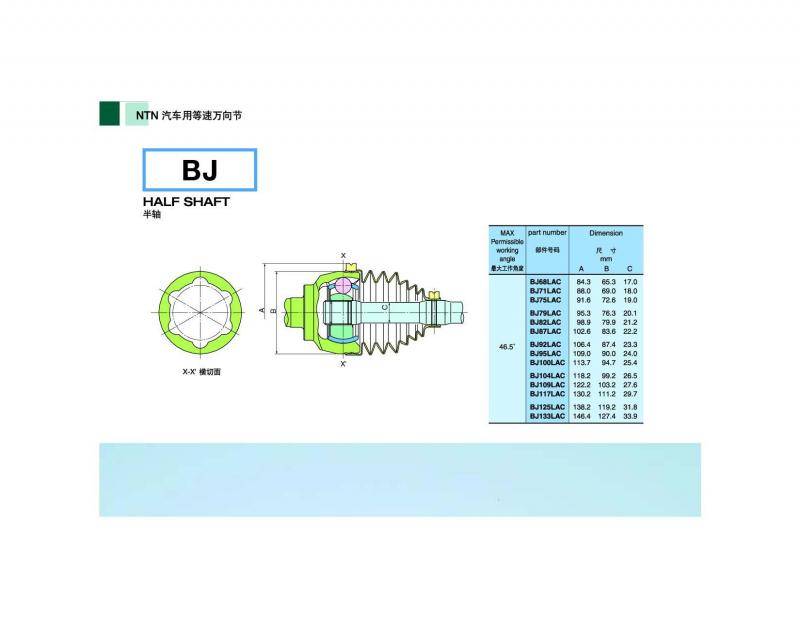

Some information on the 2010 F150/Navigator inner axle hub I plan to use with my MK8 carrier: The attached image shows numerous dimensions. But I have a problem: The axle seal used with the F150 inner axle stub has a bore diameter of 1.811" and a housing diameter of 2.883. The Mark 8 carrrier housing has a housing bore of 2.41" I have not been able to find an axle seal for a 1.811" shaft with a housing bore of 2.41" Closest seal I can find has a 2.445 OD. This means I have to get the carrier seal bore machined to a larger diameter.

- (I could go with a Cobra 31 splined inner, but the F150 appears to be stronger and uses a 37 spline axle, versus the Cobra's 35 spline axle.)

Any comments or thoughts for different approaches?

- (I could go with a Cobra 31 splined inner, but the F150 appears to be stronger and uses a 37 spline axle, versus the Cobra's 35 spline axle.)

Any comments or thoughts for different approaches?

Last week I wrote Timken asking if they had an axle seal in the dimensions I am looking for. They wrote back with a couple of P/Ns. Looks like one of them will work. It is interesting that when I researched the P/N, several auto parts suppliers carry them, but there are no vehicle applications listed. Once I prove out that the seal works, I'll post the number in case other want to go down this path.

Since I have a sealing solution, I went ahead and ordered the rest of the parts to rebuild my Mark VIII carrier. Torsen T-2R Differential, M-4210-B1 rebuild kit, axle bearings and the new seals. I went ahead and ordered a second F150 Axle.

Can anyone recommend the best and most cost effective IRS half-shaft manufacturer?

(Seals arrived, and didn't work. - Back to searching for a sealing solution)

Since I have a sealing solution, I went ahead and ordered the rest of the parts to rebuild my Mark VIII carrier. Torsen T-2R Differential, M-4210-B1 rebuild kit, axle bearings and the new seals. I went ahead and ordered a second F150 Axle.

Can anyone recommend the best and most cost effective IRS half-shaft manufacturer?

(Seals arrived, and didn't work. - Back to searching for a sealing solution)

Last edited:

Ranchero50

Well-Known LVC Member

You could get the stub shaft seal diameter turned down to a common seal size. Might be PITA hard but should be machinable.

Chicago Rawhide is another good seal company. I think SKF is too. I installed a 160mm x 200mm x 12mm seal last night in the folder on one of our printing presses. The SKF 23222 bearing was around $2800.

Chicago Rawhide is another good seal company. I think SKF is too. I installed a 160mm x 200mm x 12mm seal last night in the folder on one of our printing presses. The SKF 23222 bearing was around $2800.

You could get the stub shaft seal diameter turned down to a common seal size. Might be PITA hard but should be machinable.

Chicago Rawhide is another good seal company. I think SKF is too. I installed a 160mm x 200mm x 12mm seal last night in the folder on one of our printing presses. The SKF 23222 bearing was around $2800.

I believe I have to go the other way. Finding seals for a 46mm/1.812" shaft is easy, it is the OD that is the problem. I will most likely have to have the carrier housing seal opening opened slightly to fit a 62mm OD seal.

Ranchero50

Well-Known LVC Member

From a machinists perspective holding the housing in the mill is going to be a big PITA although if you plan on breaking axles it might be cheaper to do that work once vs. turn down several stub shafts.

From a machinists perspective holding the housing in the mill is going to be a big PITA although if you plan on breaking axles it might be cheaper to do that work once vs. turn down several stub shafts.

I don't think I would have it milled, I would have it bored out via a CNC, where the housing is mounted flush on the table and the CNC head comes in from each side and bores open the hole.

I thought about getting the stub turned down, but aren't the stubs hardened and wouldn't machining down the diameter make the part weaker?

HELP! Has anyone successfully removed the axle from the outer CV joint?

Either I am missing something in taking it apart or doing something wrong!

I am assuming it is like most outer CV joints that use a C-ring that compresses and then expands once the axle is pushed into the CV race.

To date I have tried:

1. Slide tube where you put the Outer CV flush to a plate on the end of a tube and then slam the tube down so that the weight of the axle compresses the circlip and the axle falls out.

2. I put it in my press, and loaded up one side of the inner face, using a bearing splitter held to the axle. I put so much force on it that the press started to flex. Then with it under as much load as I could muster, I knocked the crap out of the other side with a drift and 3 lb sledge.

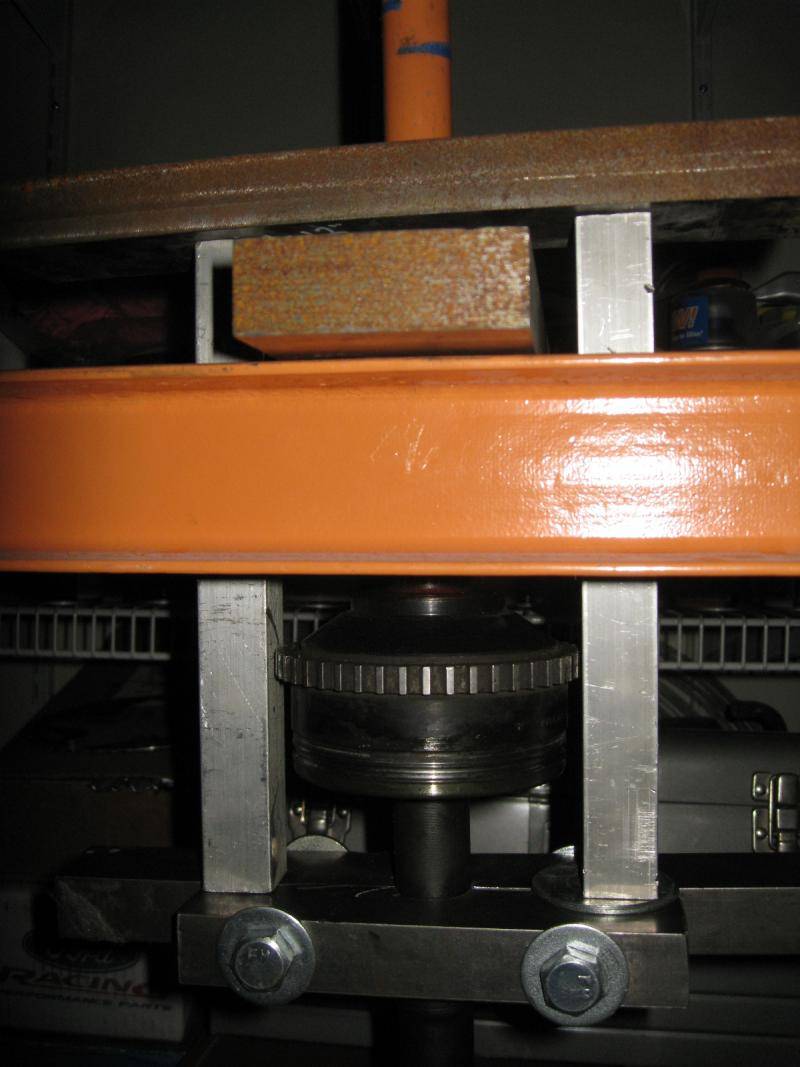

3. I built a separator based on an approach I found on the interned. I spent about 3 hours making it. I tighten it up so much that I can't add anymore load.

4. I heated up the CV joint with it under load. Nothing!

What am I missing here? Shouldn't it come apart?

Is there a known tool that I can purchase that will do this job?

Either I am missing something in taking it apart or doing something wrong!

I am assuming it is like most outer CV joints that use a C-ring that compresses and then expands once the axle is pushed into the CV race.

To date I have tried:

1. Slide tube where you put the Outer CV flush to a plate on the end of a tube and then slam the tube down so that the weight of the axle compresses the circlip and the axle falls out.

2. I put it in my press, and loaded up one side of the inner face, using a bearing splitter held to the axle. I put so much force on it that the press started to flex. Then with it under as much load as I could muster, I knocked the crap out of the other side with a drift and 3 lb sledge.

3. I built a separator based on an approach I found on the interned. I spent about 3 hours making it. I tighten it up so much that I can't add anymore load.

4. I heated up the CV joint with it under load. Nothing!

What am I missing here? Shouldn't it come apart?

Is there a known tool that I can purchase that will do this job?

Last edited:

Nobody has chimed in with any techniques to get the axle separated from the outer CV stub's inner race.

This has been a frustrating endeavor.

- I modified my aluminum based fixture to fit in my press. I loaded up the fixture and all I did was bend the 1 X 1.5" aluminum parts.

- I am in the process of machining new fixture plates out of 1 X 1.5" steel. Hopefully this updated design will let me press apart the axle.

- In the mean time, I took apart the axles from their outer CV stub from the donor axles by using only a slide tube. No Problem, they came right apart.

I have come to the conclusion that the C rings are stuck open by solidified grease or contamination and they will have to be sheared off in order to get the axle apart.

I am still hoping for someone to post their technique to remove stubborn axles...

This has been a frustrating endeavor.

- I modified my aluminum based fixture to fit in my press. I loaded up the fixture and all I did was bend the 1 X 1.5" aluminum parts.

- I am in the process of machining new fixture plates out of 1 X 1.5" steel. Hopefully this updated design will let me press apart the axle.

- In the mean time, I took apart the axles from their outer CV stub from the donor axles by using only a slide tube. No Problem, they came right apart.

I have come to the conclusion that the C rings are stuck open by solidified grease or contamination and they will have to be sheared off in order to get the axle apart.

I am still hoping for someone to post their technique to remove stubborn axles...

It's been about a week and no one has responded on better techniques to pull the axle from the CV joint.

I built another fixture out of 1" thick steel top and bottom plates. I loaded the axles up in a 12 ton press and the axle still wont pop out. I loaded up 3 different axles and they all do the same thing. When I load up the press up to its limit, the cross brace starts bowing!

- Next step is to load them up on a 20 or 30 ton press.

- I have confirmed that the NTN CV joint is a "C" clip style. for some unknown reason, it wont compress and let the axle slide out.

Still looking for ideas....

I built another fixture out of 1" thick steel top and bottom plates. I loaded the axles up in a 12 ton press and the axle still wont pop out. I loaded up 3 different axles and they all do the same thing. When I load up the press up to its limit, the cross brace starts bowing!

- Next step is to load them up on a 20 or 30 ton press.

- I have confirmed that the NTN CV joint is a "C" clip style. for some unknown reason, it wont compress and let the axle slide out.

Still looking for ideas....

Last edited:

For whomever is following this thread, I spoke with a couple of axle refurbishing companies regarding removing the outer splined axle from the inner bearing. They confirmed that it is fairly common for the "C" rings to bend or expand over the years and there are only 2 ways to get the axle apart. 1. Shatter the bearing cage and remove the pieces so there is room the take out the inner race, or 2. Press off the axle by shearing the "C" ring into pieces. They stated one will typically need a 30 ton or greater press to do this. (20 ton press, may not be enough!)

I am on the prowl for a cost effective 30 ton press, but the cost goes up 2.5X more than a typical 20 ton press.

I am on the prowl for a cost effective 30 ton press, but the cost goes up 2.5X more than a typical 20 ton press.

For whomever is following this thread.

I poke around in here every once in awhile.

chris2523

93 Mark VIII

For whomever is following this thread

i am also following. pretty interesting information.

Nobody has chimed in with any techniques to get the axle separated from the outer CV stub's inner race.

This has been a frustrating endeavor.

I am still hoping for someone to post their technique to remove stubborn axles...

I don't mean to be a ball buster but:

Your not going to find alot of support for what your trying to acomplish because people that are pumping 500+hp through CV shafts have a complete custom shaft built.

I don't mean to be a ball buster but:

Your not going to find alot of support for what your trying to acomplish because people that are pumping 500+hp through CV shafts have a complete custom shaft built.

I've had quotes in the range of $1800 to $2600 for a custom set of half- shafts.

I'll end up having around $1K in a pair of semi-custom axles that will handle 600+ HP. This it is worth it to me to take the time to spec and do it myself to save $1.2K. I have an axle fabricator lined up to machine and spline custom center axles as soon as I can get the axle apart and can send them the inner bearing races to match up the splines.

The main problem is that the 3 different outer stubs used on the LS, T-Bird and S-types are unique to the DEW98 platform. I'll use the strongest outer stub, with a special hardened inner bearing race, cage, custom inner axles, and a heavy duty 31 spline inner CV stub, and I'll be good to go.

(FYI, Custom machined outer stubs cost close to $800 a pair.)

From one perspective, I am going through this exercise so that as our cars get older we will have other cost effective options to keep them going and/or be able to upgrade them when part are no longer available. Since I am going to use a Mark VIII IRS pumpkin, I decided to go with a 31 spline carrier to get added strength. This requires a different inner CV stub, so I decided to go with something off-the-shelf that is stronger than the Cobra 31 spline inner axle stub.

I was finally able to press off one of the axles out of the CV inner race. The "C" ring sheared in half, and half of the axle teeth on the outside of the "C" ring sheared off. I am glad to finally have one apart. The internals of the outer CV look in good shape, except one bearing shows signs of wear.

Hopefully in the next couple weeks, I will get custom center axles on order.

Hopefully in the next couple weeks, I will get custom center axles on order.

baxter

New LVC Member

Would you send along a brief update on your axle project? After weeks of internet search it appears you are the only private party that's found a more cost effective way to upgrade the 8.8 stub shafts.

Thanks,

Kevin

Thanks,

Kevin

Sorry that I haven't posted any updates on axle upgrades. This is in part because I completely shifted directions and decided to ditch the stock S-type/LS hub carrier. I decided to use Corvette C5/C6 spindles and design my own upper and lower control arms. This eliminated numerous problems I was having with the rotor diameter and brake calipers/parking brake. I benefited from a much stronger hub that directly fits the corvette rims I am using on the car. Using Corvette spindles/hubs makes it a lot easier to match up the splined axles for the inner CV hub stub. It also became a more interesting project.... I am still waiting on the fabrication of custom ball studs to mate to my new control arms to the Corvette spindles.

Hopefully progress will be faster in 2014 than last year...

Hopefully progress will be faster in 2014 than last year...

baxter

New LVC Member

Joe,

If any of these assumptions from your previous posts aren't correct would you please amend:

you are currently using;

the lincoln mark 8 irs center section housing with torsen 2r 31 spline diff,

2010 f150/navigator inner stub axles.

What inner stub axle seal did you end up using and what's needed to make this work?

Did you find an easier way to disassemble the stub axle cv joint?

Thanks,

Kevin

If any of these assumptions from your previous posts aren't correct would you please amend:

you are currently using;

the lincoln mark 8 irs center section housing with torsen 2r 31 spline diff,

2010 f150/navigator inner stub axles.

What inner stub axle seal did you end up using and what's needed to make this work?

Did you find an easier way to disassemble the stub axle cv joint?

Thanks,

Kevin

I am slowly building up a complete rear sub-frame suspension and drivetrain.

- The subframe is a 2005 LS K-frame with new front differential mounts welded in place to fit a Mark 8 carrier housing.

- Carrier housing is a Mark 8 housing with the axle shaft seal bores modified to fit the heaviest duty off-the-shelf inner CV hub I could find.

- Carrier is fitted with a Torsen T2R 31 splined LSD.

- The seals I used, only available one for this combination, including many hours of calling suppliers and calling manufacturers is: National Seal, P/N 451817. 1.812 x 2.43 x 0.468. (My little secret, now shared with the rest of the world)

The inner CV hub that works for this set-up is from the "Left front" CV joint 1/2 Shaft from 07-'10 Expedition, 09-'10 F150, 4WD Years:2009-2010 (X 2 - one fore each side.)

- I have built up C5 spindle assemblies with 14.4" rear rotors with 2010+ Camaro Brembo Calipers, and the "big plus" to this is the much heavier duty hub that use beefier Corvette CV axles, and has the built in Rotor Parking brake assembly.

- Custom Upper and lower Control arms. (My design, not posting images of these until the complete build is finished.)

- I will be able to use the longer stock C5/C6 splined axle shafts and have the inner end shortened and splined to mate with the Expedition CV spider gear.

- I am using 19 x 12 Corvette rims on back, and in order to achieve this, fender flares are required. Plus in the design of the control arms, I am increasing their lengths (Wider stance) so that the rim's offsets match up in the same relative position as stock Jaguar STR rear rims. ( I didn't want to use rim spacers/adapters, and was worried about more scrub having 4"wider rims further outboard.)

- Coilover shocks and springs are selected, but not purchased. I still have 3-4 other custom parts to purchase before ordering these.

I spent way too many hours trying to find a better/stronger outer hub assembly to use, and I couldn't find any off-the shelf replacements for the hub with that wide press in hub carrier bearing. This outer hub/bearing/spindle combination is unique to the DEW98 platform. This meant that any direction I chose would require more custom fabricated $$$$ parts.

If others chose to put in a 31 splined 8.8 differential, rather than the standard 28 spline, and stick with the stock outer CV stubs, custom splined axles will be required. This alone will cost $600 to $800 for a pair of Driveshaftshop custom splined axles. I was also worried that all of the versions of LS and Jaguar splined axles and CV races are too weak, and you'de have to use 300M axles at a minimum because of the smaller diameter splines that are used. If you have an extra $1500 to $2500, you could save a lot of time and have custom CV 1/2 shafts made. Could save a lot of headaches.

Lastly, I happily shifted to the Vette hub because the ABS reluctors in the hub are compatible with my conversion, Others will have to maintain the LS style Reluctor rings and their associated sensors.

Enjoy!

- The subframe is a 2005 LS K-frame with new front differential mounts welded in place to fit a Mark 8 carrier housing.

- Carrier housing is a Mark 8 housing with the axle shaft seal bores modified to fit the heaviest duty off-the-shelf inner CV hub I could find.

- Carrier is fitted with a Torsen T2R 31 splined LSD.

- The seals I used, only available one for this combination, including many hours of calling suppliers and calling manufacturers is: National Seal, P/N 451817. 1.812 x 2.43 x 0.468. (My little secret, now shared with the rest of the world)

The inner CV hub that works for this set-up is from the "Left front" CV joint 1/2 Shaft from 07-'10 Expedition, 09-'10 F150, 4WD Years:2009-2010 (X 2 - one fore each side.)

- I have built up C5 spindle assemblies with 14.4" rear rotors with 2010+ Camaro Brembo Calipers, and the "big plus" to this is the much heavier duty hub that use beefier Corvette CV axles, and has the built in Rotor Parking brake assembly.

- Custom Upper and lower Control arms. (My design, not posting images of these until the complete build is finished.)

- I will be able to use the longer stock C5/C6 splined axle shafts and have the inner end shortened and splined to mate with the Expedition CV spider gear.

- I am using 19 x 12 Corvette rims on back, and in order to achieve this, fender flares are required. Plus in the design of the control arms, I am increasing their lengths (Wider stance) so that the rim's offsets match up in the same relative position as stock Jaguar STR rear rims. ( I didn't want to use rim spacers/adapters, and was worried about more scrub having 4"wider rims further outboard.)

- Coilover shocks and springs are selected, but not purchased. I still have 3-4 other custom parts to purchase before ordering these.

I spent way too many hours trying to find a better/stronger outer hub assembly to use, and I couldn't find any off-the shelf replacements for the hub with that wide press in hub carrier bearing. This outer hub/bearing/spindle combination is unique to the DEW98 platform. This meant that any direction I chose would require more custom fabricated $$$$ parts.

If others chose to put in a 31 splined 8.8 differential, rather than the standard 28 spline, and stick with the stock outer CV stubs, custom splined axles will be required. This alone will cost $600 to $800 for a pair of Driveshaftshop custom splined axles. I was also worried that all of the versions of LS and Jaguar splined axles and CV races are too weak, and you'de have to use 300M axles at a minimum because of the smaller diameter splines that are used. If you have an extra $1500 to $2500, you could save a lot of time and have custom CV 1/2 shafts made. Could save a lot of headaches.

Lastly, I happily shifted to the Vette hub because the ABS reluctors in the hub are compatible with my conversion, Others will have to maintain the LS style Reluctor rings and their associated sensors.

Enjoy!