EsaEsLaElEs

LVC Member

Coolant leak! Car is overheating! Degas bottle looks fine, What can it be? Where is my coolant going? Where is this problem?

I didn't plan this effort from the start but considering the countless pictures taken for my own reference . . . If only I would've looked closer at my own pictures during the hasty reassembly. As far as the order of doing this, there might be as many ways as there are owners (and mechanics) who do it; one way is to just start disconnecting and removing, which is why I took so many pictures; time-consuming but would've saved me some trouble if I bothered to look closer at those pictures in my race to reassemble. If there are wrong ways to the order of it I found most of them! I'll learn from it and return to this to remind myself for the next time (of what not to do!).

Most steps are re-organized from how it was done to a much, much more SENSIBLE way, as you'll notice by the pictures. For example: not yet having the wrench to remove the EGR module, I proceeded to remove the Crossover/Thermostat Assembly just for the sake of progress - this was a terrible mistake.

This may be more than a day or 2 job the first time but If done a 2nd time it would be much simpler and faster. Disassembly was during the 3 weeks of wait-wait-waiting for parts to arrive - 20 days!

Someone else can add their own comprehensive list of tools necessary, I'll mention a few along the way (I really wish I had the proper hose clamp tool).

RH will refer to passenger side, LH to driver side.

Start with this:

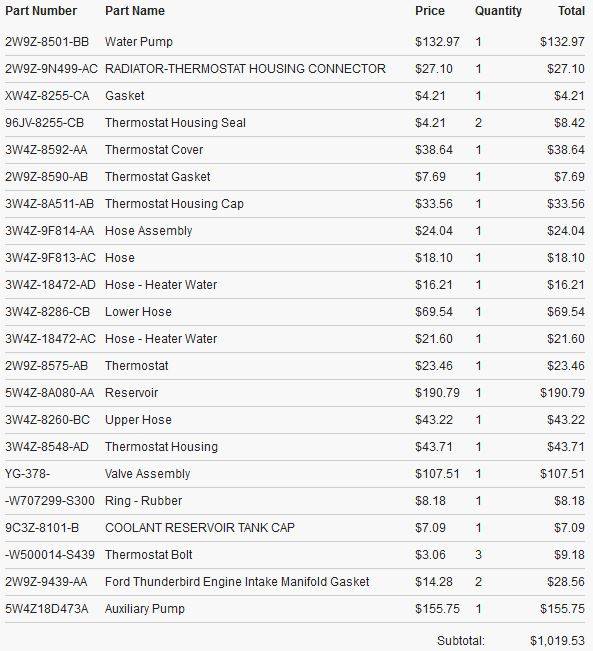

. . . and these (all parts arrived, I checked them off):

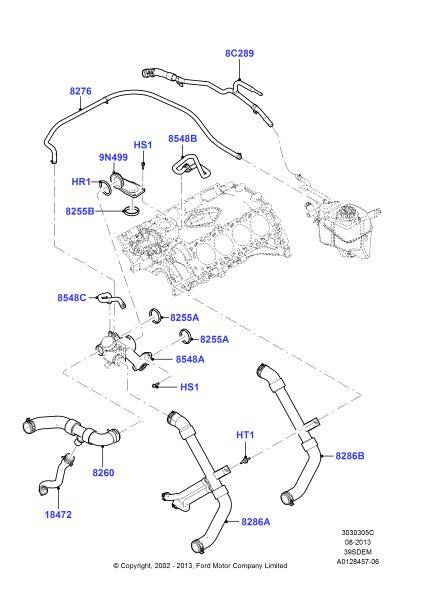

Several (not all) parts involved - with shortened "callout" numbers:

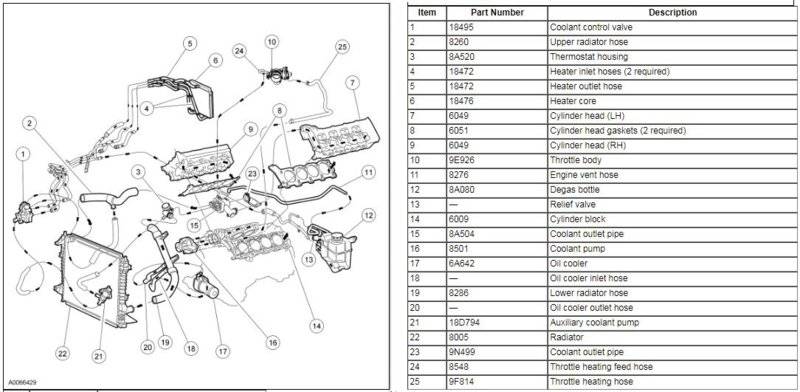

Coolant Flow diagram. The obvious difference I can see here from my 2004 is that the DCCV (2004) only has 3 hoses to it. My Coolant Auxiliary Pump has the hose coming out the top of it to the heater core hose, not to the DCCV.

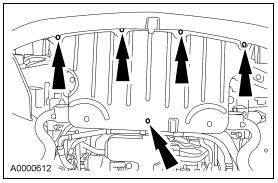

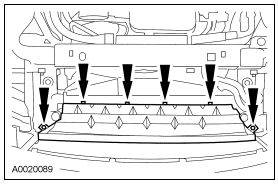

1a. Remove the splash shield. There are 7 screws (including the back ones) (5mm or 7/32) and one plastic holding fastener.

1b. I also removed the Radiator Protect Shroud as well as the 2 side-piece splash shields. Probably not necessary.

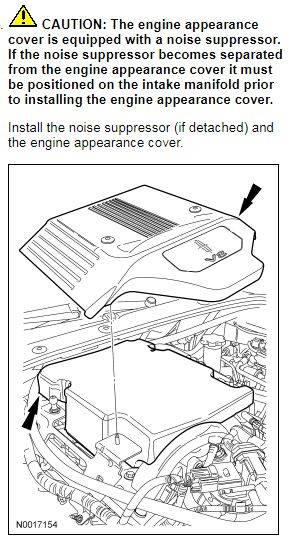

1c. Engine appearance cover off.

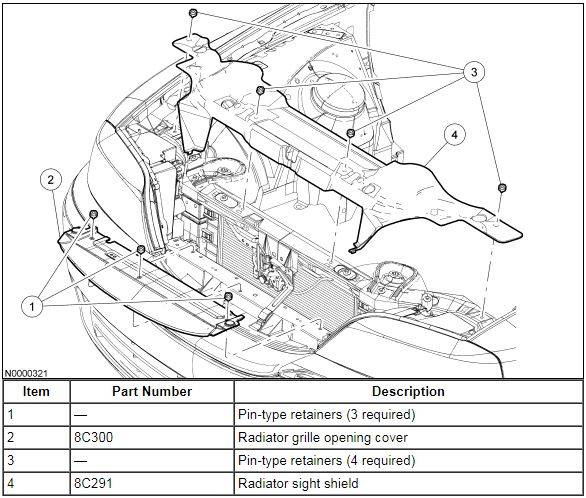

1d. Radiator Sight shield off at the top, 4 plastic retainers/fasteners.

2. De-pressurize Fuel System

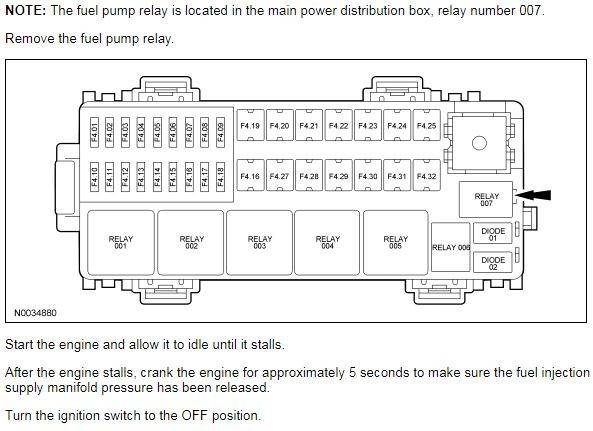

2a. In the trunk (by the battery) open the fuse box and remove the Fuel Pump Relay, number 007.

2b. Start the car and let it die. Wait a few moments and turn it over again shortly.

2c. Battery: now is a good time to disconnect negative on battery. Or If the car has been sitting long, both - and + and put a charger to it. 8 mm open-end wrench.

3. Coolant Draining:

Cooling System Draining, Filling and Bleeding

3a. Open the Degas Bottle pressure cap. Have containers ready for coolant. Don't open the engine fill cap during the drain process, only Degas cap.

3b. At RH underside of radiator is the coolant draincock (19mm). There are 2 oil lines that get in the way of the draincock, push them aside or tie one or both aside. Loosen the Draincock with 19mm open-end wrench or socket with extension.

3C. NOTE the Shop Manual instructions: "disconnect the coolant return hose at the oil cooler". The oil cooler is what the oil filter is screwed onto. The 2 smaller hoses that drop from the Lower Radiator Hose go to that. This will be done in step 10 anyway so have the container(s) there for that. Also: "Close the radiator draincock when finished." Maybe after that step . . . or anytime before coolant fill!

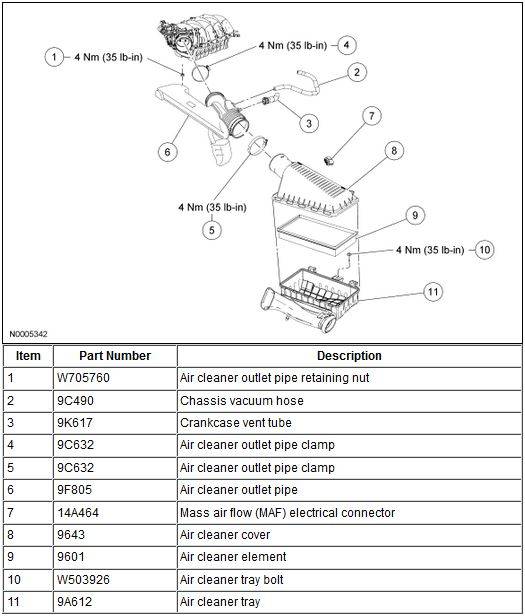

4. Air Filter/Air Cleaner Pipe assembly - ENGINE AIR CLEANER OUTLET TUBE

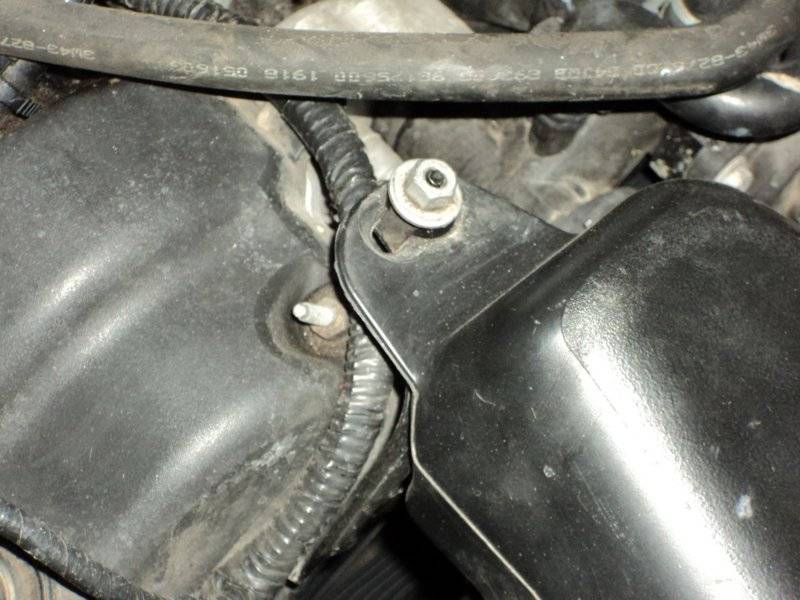

4a. Remove one 11mm "retaining" nut at the RH side of assembly (passenger side).

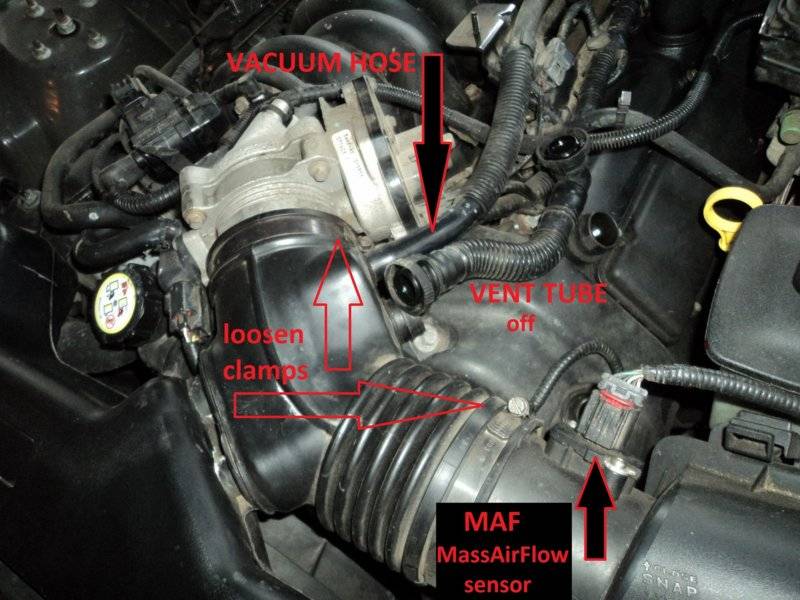

4b. "Chassis Vacuum Hose" off Air cleaner asy. (btw, this vacuum hose is the one that goes to the back of the engine which will be the last step before the Manifold comes out).

4c. Crankcase Vent Tube removed at both ends. The double O-rings at each end make them a snug fit and difficult. I cracked one outer ring plastic but it didn't matter (as bad as that sounds).

4d. Mass Air Flow (MAF) Sensor connector off (red slide up, tab under red slide pushed in, pull connector out).

4e. Not by the book, but I removed the upper air filter cover first (clamp loosened, of course). I sprayed soapy water around the boot fitting to push it away. The front of the filter cover needs to be tilted up and forward (toward headlight) to clear the lower 5 plastic holding protrusions(?) from lower half of the air filter/airbox called the tray.

I then removed the "Air cleaner Outlet", the largest piece of it, again using soapy water sprayed to free it up from the Throttle Body.

4f. One bolt holding the tray (lower half of air filter airbox), remove the filter tray.

"I don't want to go around replacing everything, much rather zero in on whats going on."

joegr said:Well, you're probably screwed then. What is going on is that all of the not replaced plastic parts are failing. You can keep going the one at a time route, but they all degrade at about the same rate. Replace the main leaker, and the added pressure just moves the problem to the next weakest part. Do it all at once and enjoy the car

SlickLS said:+1,000,000 this issue has been beat to death

I didn't plan this effort from the start but considering the countless pictures taken for my own reference . . . If only I would've looked closer at my own pictures during the hasty reassembly. As far as the order of doing this, there might be as many ways as there are owners (and mechanics) who do it; one way is to just start disconnecting and removing, which is why I took so many pictures; time-consuming but would've saved me some trouble if I bothered to look closer at those pictures in my race to reassemble. If there are wrong ways to the order of it I found most of them! I'll learn from it and return to this to remind myself for the next time (of what not to do!).

Most steps are re-organized from how it was done to a much, much more SENSIBLE way, as you'll notice by the pictures. For example: not yet having the wrench to remove the EGR module, I proceeded to remove the Crossover/Thermostat Assembly just for the sake of progress - this was a terrible mistake.

This may be more than a day or 2 job the first time but If done a 2nd time it would be much simpler and faster. Disassembly was during the 3 weeks of wait-wait-waiting for parts to arrive - 20 days!

Someone else can add their own comprehensive list of tools necessary, I'll mention a few along the way (I really wish I had the proper hose clamp tool).

RH will refer to passenger side, LH to driver side.

Start with this:

. . . and these (all parts arrived, I checked them off):

Several (not all) parts involved - with shortened "callout" numbers:

Coolant Flow diagram. The obvious difference I can see here from my 2004 is that the DCCV (2004) only has 3 hoses to it. My Coolant Auxiliary Pump has the hose coming out the top of it to the heater core hose, not to the DCCV.

1a. Remove the splash shield. There are 7 screws (including the back ones) (5mm or 7/32) and one plastic holding fastener.

1b. I also removed the Radiator Protect Shroud as well as the 2 side-piece splash shields. Probably not necessary.

1c. Engine appearance cover off.

1d. Radiator Sight shield off at the top, 4 plastic retainers/fasteners.

2. De-pressurize Fuel System

2a. In the trunk (by the battery) open the fuse box and remove the Fuel Pump Relay, number 007.

2b. Start the car and let it die. Wait a few moments and turn it over again shortly.

2c. Battery: now is a good time to disconnect negative on battery. Or If the car has been sitting long, both - and + and put a charger to it. 8 mm open-end wrench.

3. Coolant Draining:

Cooling System Draining, Filling and Bleeding

3a. Open the Degas Bottle pressure cap. Have containers ready for coolant. Don't open the engine fill cap during the drain process, only Degas cap.

3b. At RH underside of radiator is the coolant draincock (19mm). There are 2 oil lines that get in the way of the draincock, push them aside or tie one or both aside. Loosen the Draincock with 19mm open-end wrench or socket with extension.

3C. NOTE the Shop Manual instructions: "disconnect the coolant return hose at the oil cooler". The oil cooler is what the oil filter is screwed onto. The 2 smaller hoses that drop from the Lower Radiator Hose go to that. This will be done in step 10 anyway so have the container(s) there for that. Also: "Close the radiator draincock when finished." Maybe after that step . . . or anytime before coolant fill!

4. Air Filter/Air Cleaner Pipe assembly - ENGINE AIR CLEANER OUTLET TUBE

4a. Remove one 11mm "retaining" nut at the RH side of assembly (passenger side).

4b. "Chassis Vacuum Hose" off Air cleaner asy. (btw, this vacuum hose is the one that goes to the back of the engine which will be the last step before the Manifold comes out).

4c. Crankcase Vent Tube removed at both ends. The double O-rings at each end make them a snug fit and difficult. I cracked one outer ring plastic but it didn't matter (as bad as that sounds).

4d. Mass Air Flow (MAF) Sensor connector off (red slide up, tab under red slide pushed in, pull connector out).

4e. Not by the book, but I removed the upper air filter cover first (clamp loosened, of course). I sprayed soapy water around the boot fitting to push it away. The front of the filter cover needs to be tilted up and forward (toward headlight) to clear the lower 5 plastic holding protrusions(?) from lower half of the air filter/airbox called the tray.

I then removed the "Air cleaner Outlet", the largest piece of it, again using soapy water sprayed to free it up from the Throttle Body.

4f. One bolt holding the tray (lower half of air filter airbox), remove the filter tray.