Maintenance - Cooling System Overhaul

Since I've decided to keep the LS for a while longer and with winter approaching, it was time to tackle one of the most dreaded points of failure on these cars: the plastic cooling system.

Partslist:

[table="width: 500, class: grid"]

[tr]

[td]

Name[/td]

[td]

Part #[/td]

[td]

Qty[/td]

[/tr]

[tr]

[td]Upper Radiator Hose[/td]

[td]3W4Z-8260-BB[/td]

[td]1[/td]

[/tr]

[tr]

[td]Lower Radiator Hose[/td]

[td]3W4Z-8286-CB[/td]

[td]1[/td]

[/tr]

[tr]

[td]Plastic Elbow[/td]

[td]2W9Z-9N499-AC[/td]

[td]1[/td]

[/tr]

[tr]

[td]Main crossover/T[/td]

[td]3W4Z-8548-AD[/td]

[td]1[/td]

[/tr]

[tr]

[td]T-Stat Housing[/td]

[td]3W4Z-8592-AA[/td]

[td]1[/td]

[/tr]

[tr]

[td]T-Stat[/td]

[td]2W9Z-8575-AB[/td]

[td]1[/td]

[/tr]

[tr]

[td]O-Ring: Block -> Elbow[/td]

[td]XW4Z-8255-CA[/td]

[td]1[/td]

[/tr]

[tr]

[td]O-Ring: Elbow -> Main Crossover/T[/td]

[td]W707299-S300[/td]

[td]1[/td]

[/tr]

[tr]

[td]O-Ring: Main Crossover/T -> Block[/td]

[td]96JV-8255-CB[/td]

[td]2[/td]

[/tr]

[tr]

[td]O-Ring: Main Crossover/T -> T-Stat Housing[/td]

[td]2W9Z-8590-AB[/td]

[td]1[/td]

[/tr]

[/table]

Thanks to SoulSoak and other LvC members for compiling this list. I provide full P/Ns. Most items were purchased from RockAuto. Upper hose, elbow and crossover pipe from the dealer at wholesale pricing.

Degas was already preventively replaced last year, along with the idler pulley, belt and tensioner.

Parts laid out:

T-stat and housing:

Assembled:

Main elbow, showing the shorter bolts I intended to use. Big thanks to Andrizzle for letting me know me the t-stat housing bolts are just the perfect length to fit here. No cutting of new bolts necessary!

Parts laid out:

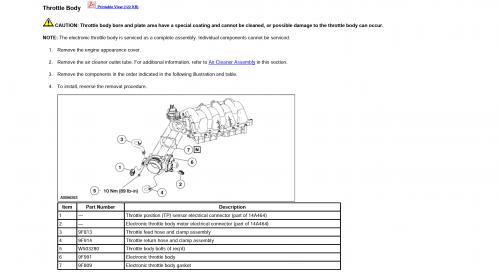

TB removed:

As I started on the housing, I noticed something was off. One of the tabs holding the thermostat in place was broken. This explains the long warmup times in cold weather:

Getting the lower hose off the oil cooler WAS A BITCH.

I chose to go to the TB route and cut, as opposed to removing the entire manifold.

I broke it down to about two days of work, not too bad of a project. Upper and lower house and the plastic elbow didn't show any signs of fatigue, but I am glad they were all replaced anyway. I bled the car and downloaded an OBD2 app for my phone to monitor coolant temperatures for the new fays days. All is good.

A big thank you goes out to SoulSoak, TooManyToys, joegr, Andrizzle and other members who of shared tons of valuable information on here, and of course owlman for uploading the service manual online.

Cost: $450