Apply penetrating fluid to old studs, gently wire brush studs, clean up studs, new fresh lugnuts,

small dab of anti-seize inside lugnuts, torq to spec, drive to work and back

then retorq to spec again, double check torq following week.

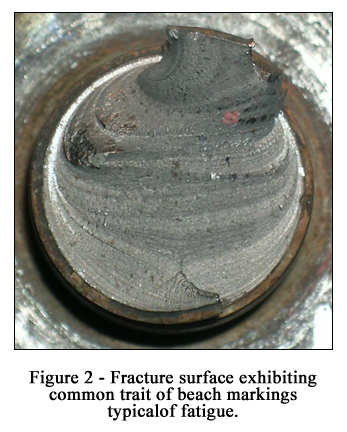

Do

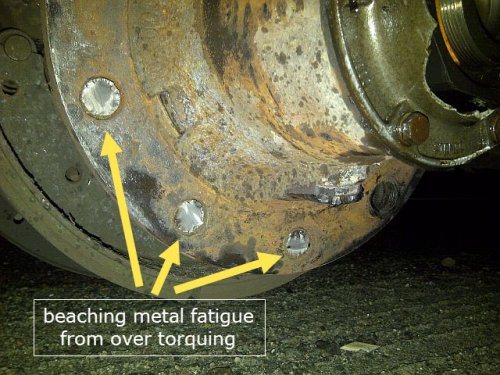

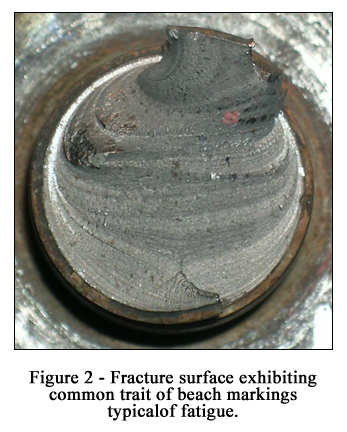

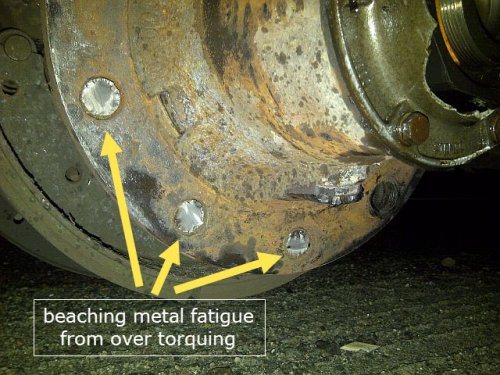

NOT overtighten lug nuts past recommended torq specs,

... or this could happen to you also,

sample:

Additionally

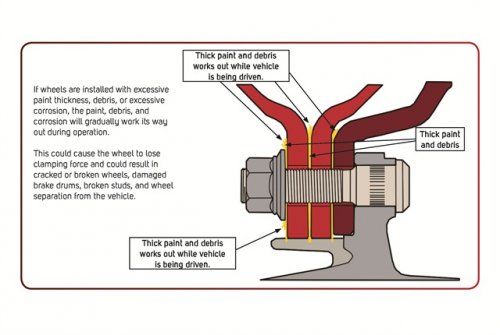

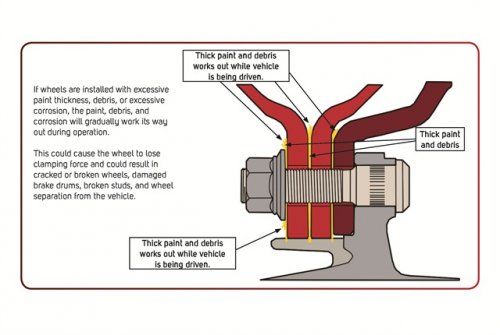

Additionally when you have the wheels off for service it's important to wire brush the back of the rim,

inside where it meets the hub and the hub itself in and around the studs, clean this up and get rid of all

that old rust build up, this will ensure an all-even

clamping force wheel onto hub seating.

----EDIT: Matting surfaces. inside rim to hub.

Cross tighten the lug nuts onto the studs to further ensure an even clamping force onto the hub.

(and yeah, the company above took a major hit to their operating authority due to improper maintenance processes.)

(I took a lighter slap across the fingers due to being the responsible operator in charge of involved equipment.)

(don't bother with the flaming of truck drivers, I've heard it a thousand times by now, SH*T happens, no one died!)

Please don't take lugnuts/studs for granted, take the time to do it right,

buy a torque wrench please!

Look up the involved manufactures' recommended torque specifications for what ever you tighten down.