I got off work early yesterday and finally put this thing together.

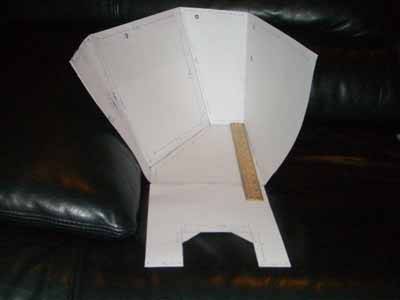

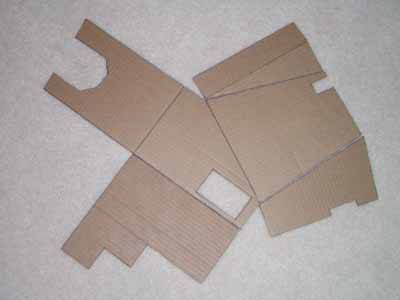

As I have posted before, I used the top of stock air box and some tubing (pic.1) to make an air scoop that brings air from the front bumper (pic.2: arrow) to the hole (pic.3). I made some measurements (pic. 4) then made a template using cardboard box (pic.5). It fits nicely in the spot (pic.6).

I bought some ABS plastic sheet and glue at a local plastic store. after few hours of cutting and fitting (I only have hand held dremel tool) I made the box (pic.7). and the final product with KKM filter (pic.8). why no top? It fits perfect and only leaves about 1cm space from the hood so I dont think it would be needed.

As I have posted before, I used the top of stock air box and some tubing (pic.1) to make an air scoop that brings air from the front bumper (pic.2: arrow) to the hole (pic.3). I made some measurements (pic. 4) then made a template using cardboard box (pic.5). It fits nicely in the spot (pic.6).

I bought some ABS plastic sheet and glue at a local plastic store. after few hours of cutting and fitting (I only have hand held dremel tool) I made the box (pic.7). and the final product with KKM filter (pic.8). why no top? It fits perfect and only leaves about 1cm space from the hood so I dont think it would be needed.