Here's what I did to gain manual control over my air ride system. This all began when the factory compressor took a dump on me and forced me to install a set of coils for awhile. During that time I read every writeup that had to do with aftermarket air management on our cars. I chose paddle valves because they are cheap and reliable. They mount inside the car and use 1/4" air line. The do not freeze and are less sensitive to debris. Electric valves are cool too but they would have exceeded my promise to my ol lady budget. In the end I decided on the following:

4 manual paddle valves

1/4" air line

Nickel plated ptc fittings

2 dual needle gauges

5 gallon aluminum tank

Viair 144c

Drain

Pressure relief valve

1/4 ball valve and chuck for air tools

Schrader valve just in case of comp failure

4gauge power wire

Inline fuse

Distribution fuse block

Various terminals

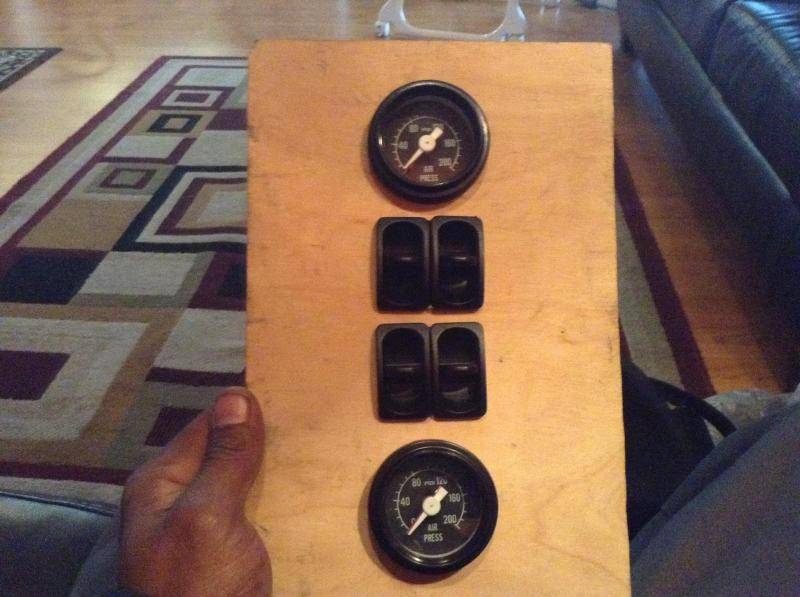

Okay first up was figuring where to mount the paddle valve setup. After numerous hours of sitting in my car and planning how I was gonna plumb 6 airlines to feed it...the only natural place was in the center console. I made a card board template and cut a piece of plywood for the panel. I sanded the edges to get a perfect fit then stained and glossed it.

4 manual paddle valves

1/4" air line

Nickel plated ptc fittings

2 dual needle gauges

5 gallon aluminum tank

Viair 144c

Drain

Pressure relief valve

1/4 ball valve and chuck for air tools

Schrader valve just in case of comp failure

4gauge power wire

Inline fuse

Distribution fuse block

Various terminals

Okay first up was figuring where to mount the paddle valve setup. After numerous hours of sitting in my car and planning how I was gonna plumb 6 airlines to feed it...the only natural place was in the center console. I made a card board template and cut a piece of plywood for the panel. I sanded the edges to get a perfect fit then stained and glossed it.