Topcat

Active LVC Member

20 years ago I was building race motors and had an idea to create a set of headers , in which each cylinder that has already exhausted , would extract the next one to exhaust, instead of only half...Standard headers due to the fact that the four pipes are gathered , in the collector , on each side of the motor , can only due above for 180 deg of motor revolution , these are called 180deg headers ...In order to become 360 deg headers a pipe on each side would need to cross over the the opposite collector.. There was no way to keep pipes the same length and piping under the motor was a nightmare.. I could never figure a way to make them to fit in a car so I never got a chance to try my idea... A few years later I was racing open motor , v8 boats , and again , figuring with the headers above the motor , I would have clearance , to keep pipes equal and crossed ...but never had the time to try the idea out...I believe the indy v8 motors may have also used this idea but i have no facts to back that belief up...

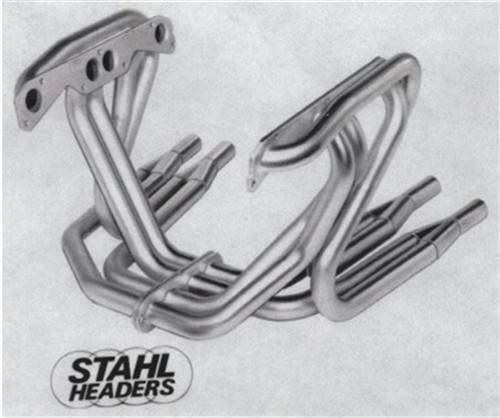

A friend of mine ,of too many years ,who was around during the planning stages of these new headers , has recently sent me this picture From Stahl Headers , a company responsible for many header innovations over the years.. One you might remember is the "tri Y " collector .. there was only two pipes in the collector...There were many others they were always experimenting with odd arrangements...

Any way here is the pic he sent me 360 deg headers ......

We want to contract Kooks Headers here on LI ,to custom make these , to fit his v8 powered kitcar..I may finally get a chance to see how well they work 20 years later...This is the answer I never came up with ... :Bang

A friend of mine ,of too many years ,who was around during the planning stages of these new headers , has recently sent me this picture From Stahl Headers , a company responsible for many header innovations over the years.. One you might remember is the "tri Y " collector .. there was only two pipes in the collector...There were many others they were always experimenting with odd arrangements...

Any way here is the pic he sent me 360 deg headers ......

We want to contract Kooks Headers here on LI ,to custom make these , to fit his v8 powered kitcar..I may finally get a chance to see how well they work 20 years later...This is the answer I never came up with ... :Bang

Last edited by a moderator: