Ready to buy from arnott everything except front struts. My friend mechanic Craig will work with me to do them in my Garage. Craig's a a bumper to bumper mechanic including dectiving electric sensor problems. My Mark is a 1996 Mark 8, 132,000. Orginal paint, no rust

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebirth of orginal air ride

- Thread starter BILLBOATS

- Start date

I think you will be happy once all is done.Ready to buy from arnott everything except front struts. My friend mechanic Craig will work with me to do them in my Garage. Craig's a a bumper to bumper mechanic including dectiving electric sensor problems. My Mark is a 1996 Mark 8, 132,000. Orginal paint, no rust

Me too, The car really never rode soft since I owned it , my 98 ford f150 truck took the bumps better than the Mark. I suspect there is a air leak making the orginal compressor run to much. Arnott has very good air product except they do not sell the Marks air struts anymore. I am looking into westar at about 280 each x 2=560.00. They are out of Maryland. They guarantee them for 2 years. If they were arnott's guarantee its life time. I get arnott for all( compressor, shocks,rear air bags) except front struts at 459.00 Some new air line 20.00 . All new selanoids for 20 each. Not sure but I 'll get them and do a return if not needed.so far its up to 1100.00. Vs conversion strutmasters . I am an older guy now and this probably will be my going home car, Whats the ride feel like in a good air ride?I think you will be happy once all is done.

I would think air would always be nicer than springs, though I never road in a M8 with springs. I think your shocks have a lot to do with ride quality.Me too, The car really never rode soft since I owned it , my 98 ford f150 truck took the bumps better than the Mark. I suspect there is a air leak making the orginal compressor run to much. Arnott has very good air product except they do not sell the Marks air struts anymore. I am looking into westar at about 280 each x 2=560.00. They are out of Maryland. They guarantee them for 2 years. If they were arnott's guarantee its life time. I get arnott for all( compressor, shocks,rear air bags) except front struts at 459.00 Some new air line 20.00 . All new selanoids for 20 each. Not sure but I 'll get them and do a return if not needed.so far its up to 1100.00. Vs conversion strutmasters . I am an older guy now and this probably will be my going home car, Whats the ride feel like in a good air ride?

I wouldn't think you need to replace the air lines unless one was damaged with some other work on the car? I have read that you are best to buy new Ford solenoids vs the new ones that come with aftermarket.

The pump works often with the car lowering and re-raising each time on the hwy. That is why I installed the module to control the height and a switch so I could turn off the system from within the interior and leave it at the height I like (hwy height all the time). So no extra use on the system raising and lowering each time on the hwy. This saves the system a lot, if you are on the hwy twice a day.

if roads are rough in an area I just raise it up for a smoother ride.

unity

Dedicated LVC Member

Air ride is always superior to coils. The car was designed for it, so refreshing it will be nice. Long, long ago I put two new OEM struts up front as part of a total system overhaul. $300 each at the time for the updated second gen units. New Ford ones can still be found sometimes floating around warehouses, but they are getting incredibly rare. The absorber inside the shock wears, so a new set of fronts will help but the majority of ride comfort comes from the rear. Thats because of the weight distribution. A rear shock absorber change will have a greater impact than fronts. Always spend good money on rear shock absorbers. The rear bags are so simple that almost any brand is fine.

When you do the fronts, make sure the strut at lower arms is tightened once full weight is on the wheel and the vehicle has settled. If you tighten it down wrong, the front will have a bouncy feel because the bushing is being twisted wrong.

The compressor is designed to operate often. There is no harm in having it run for getting on/off the highway. The compressor itself is not too hard to even rebuild. But they do wear. Basically a rebuilt or new should last over 100k miles. Most people wont have a Mark long enough to worry about replacing it yet again. I wish Ford had done the indirect method of bag inflation. That is to have a tank hold reserve air to fill the bags. The compressor runs just to keep the tank at pressure. The result is faster raising and the compressor simply maintains tank pressure instead. So it can run more often but at shorter intervals, which is much better. Heat is what kills the compressor and a lot of heat is made when it runs for longer durations.

Anyway, good luck with the refresh. Its not a difficult chore, just takes time. The best part is not needing to compress coils! Although getting the new front struts in place can be a pain.

When you do the fronts, make sure the strut at lower arms is tightened once full weight is on the wheel and the vehicle has settled. If you tighten it down wrong, the front will have a bouncy feel because the bushing is being twisted wrong.

The compressor is designed to operate often. There is no harm in having it run for getting on/off the highway. The compressor itself is not too hard to even rebuild. But they do wear. Basically a rebuilt or new should last over 100k miles. Most people wont have a Mark long enough to worry about replacing it yet again. I wish Ford had done the indirect method of bag inflation. That is to have a tank hold reserve air to fill the bags. The compressor runs just to keep the tank at pressure. The result is faster raising and the compressor simply maintains tank pressure instead. So it can run more often but at shorter intervals, which is much better. Heat is what kills the compressor and a lot of heat is made when it runs for longer durations.

Anyway, good luck with the refresh. Its not a difficult chore, just takes time. The best part is not needing to compress coils! Although getting the new front struts in place can be a pain.

I agree with Unity. The system was designed to work often, meaning long lasting. They did design the system to lower/raisse for each hwy drive and build it accordingly.

For me I'm on and off the hwy 2 to 5 times a day. With having the ASHAM 8 module and my M8 at hwy height or a bit lower all the time there is no need for the system to lower the M8 further, so I installed the suspension switch in the interior (and turn it off before entering the hwy), it saves the system working those extra 2 to 5 times a day, thus the compressor would be used that much less and last longer.

For me I'm on and off the hwy 2 to 5 times a day. With having the ASHAM 8 module and my M8 at hwy height or a bit lower all the time there is no need for the system to lower the M8 further, so I installed the suspension switch in the interior (and turn it off before entering the hwy), it saves the system working those extra 2 to 5 times a day, thus the compressor would be used that much less and last longer.

Could you elaborate more on detail of that control module , where to buy ?, location on the car, ? and the place where you put the your stitch?. I like keep the compressor off while driving say to Chicago with inflated air system. Found a westa rair sturt new for 203.00 but have to see if its waranted the same as buying it from Westar of MarylandI would think air would always be nicer than springs, though I never road in a M8 with springs. I think your shocks have a lot to do with ride quality.

I wouldn't think you need to replace the air lines unless one was damaged with some other work on the car? I have read that you are best to buy new Ford solenoids vs the new ones that come with aftermarket.

The pump works often with the car lowering and re-raising each time on the hwy. That is why I installed the module to control the height and a switch so I could turn off the system from within the interior and leave it at the height I like (hwy height all the time). So no extra use on the system raising and lowering each time on the hwy. This saves the system a lot, if you are on the hwy twice a day.

if roads are rough in an area I just raise it up for a smoother ride.

I do not know if the creator of the module is still making them. I do have his email and would reach out to him if you like - I think they were last sold at $160?

If you have a 1st gen, it will fit in the ashtray, but he doesn't have anymore face plates. I put mine in center of my dash. You will see two switches one for the suspension on/off and the other for the park drop feature (with the module you can turn this on/off by a connector or wire up a switch.

I later added a TPMS that tracks all tire pressure and temperature of each tire. The link below for full module thread

Asham 8 if you were thinking of getting one...

If you have a 1st gen, it will fit in the ashtray, but he doesn't have anymore face plates. I put mine in center of my dash. You will see two switches one for the suspension on/off and the other for the park drop feature (with the module you can turn this on/off by a connector or wire up a switch.

I later added a TPMS that tracks all tire pressure and temperature of each tire. The link below for full module thread

Asham 8 if you were thinking of getting one...

Last edited:

Thanks , Looking forward to the day my air ride is restored with the ride that goes with an air rideAir ride is always superior to coils. The car was designed for it, so refreshing it will be nice. Long, long ago I put two new OEM struts up front as part of a total system overhaul. $300 each at the time for the updated second gen units. New Ford ones can still be found sometimes floating around warehouses, but they are getting incredibly rare. The absorber inside the shock wears, so a new set of fronts will help but the majority of ride comfort comes from the rear. Thats because of the weight distribution. A rear shock absorber change will have a greater impact than fronts. Always spend good money on rear shock absorbers. The rear bags are so simple that almost any brand is fine.

When you do the fronts, make sure the strut at lower arms is tightened once full weight is on the wheel and the vehicle has settled. If you tighten it down wrong, the front will have a bouncy feel because the bushing is being twisted wrong.

The compressor is designed to operate often. There is no harm in having it run for getting on/off the highway. The compressor itself is not too hard to even rebuild. But they do wear. Basically a rebuilt or new should last over 100k miles. Most people wont have a Mark long enough to worry about replacing it yet again. I wish Ford had done the indirect method of bag inflation. That is to have a tank hold reserve air to fill the bags. The compressor runs just to keep the tank at pressure. The result is faster raising and the compressor simply maintains tank pressure instead. So it can run more often but at shorter intervals, which is much better. Heat is what kills the compressor and a lot of heat is made when it runs for longer durations.

Anyway, good luck with the refresh. Its not a difficult chore, just takes time. The best part is not needing to compress coils! Although getting the new front struts in place can be a pain.

Re reading you tips from doing a rebuild made me want to buy the best shocks and carefull how the struts are tightened down as to keep the bushing from twisting(Ithink thats what you are getting at)? I am cleaning out my garage soon , putting back all the tools I had out for that 2.4 98 water pump gran am job . Its my second one and took up a lot of time giving me a late start on re building the air ride. It will go well when I start. I'll be in touch with you and other guys when I get into questions about the air ride. I know there has to be some as there is no job where questions do not arise. Thanks .Air ride is always superior to coils. The car was designed for it, so refreshing it will be nice. Long, long ago I put two new OEM struts up front as part of a total system overhaul. $300 each at the time for the updated second gen units. New Ford ones can still be found sometimes floating around warehouses, but they are getting incredibly rare. The absorber inside the shock wears, so a new set of fronts will help but the majority of ride comfort comes from the rear. Thats because of the weight distribution. A rear shock absorber change will have a greater impact than fronts. Always spend good money on rear shock absorbers. The rear bags are so simple that almost any brand is fine.

When you do the fronts, make sure the strut at lower arms is tightened once full weight is on the wheel and the vehicle has settled. If you tighten it down wrong, the front will have a bouncy feel because the bushing is being twisted wrong.

The compressor is designed to operate often. There is no harm in having it run for getting on/off the highway. The compressor itself is not too hard to even rebuild. But they do wear. Basically a rebuilt or new should last over 100k miles. Most people wont have a Mark long enough to worry about replacing it yet again. I wish Ford had done the indirect method of bag inflation. That is to have a tank hold reserve air to fill the bags. The compressor runs just to keep the tank at pressure. The result is faster raising and the compressor simply maintains tank pressure instead. So it can run more often but at shorter intervals, which is much better. Heat is what kills the compressor and a lot of heat is made when it runs for longer durations.

Anyway, good luck with the refresh. Its not a difficult chore, just takes time. The best part is not needing to compress coils! Although getting the new front struts in place can be a pain.

unity

Dedicated LVC Member

With the front struts. Just hand tighten lower bowl at lower control arm. Then drop the front end down and air-up. To prevent a system fault, you may have to use the jacks initially to get the air-ride into a height window that wont cause an immediate fault. Once the car is at height, remove jacks and bounce it up and down gently to settle the suspension. Once its at or very close to ride height and things look good/level, tighten that lower bolt. Its a pain, because you can not lift the car to do them. Very long extensions help. You dont have to torque to spec though, just get as tight as you can so the bushing's teeth on its metal sleeve bite into the lower arm - enough that when you lift the front end back up they will not slip. Then you can tighten to spec. These same sorta teeth are found on most vehicle and most bushings. Its sorta acts as a secondary shock absorber, if that makes sense, to help get the suspension back to its sweet spot.

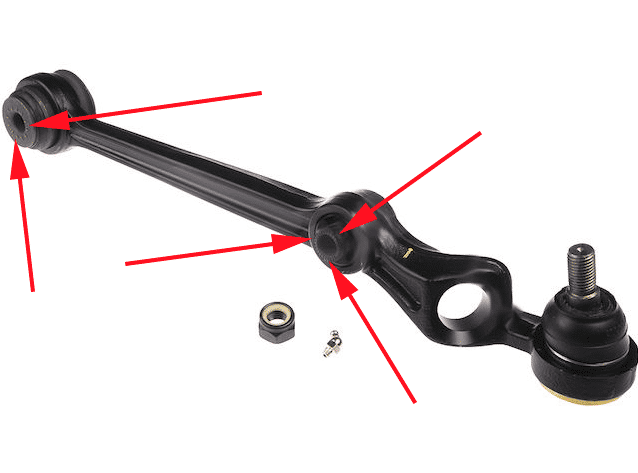

I have attached a pic of a Mark VIII lower arm. You can see the small teeth in the pic, I added some arrows. Also you can see some "teeth" at where the arm meets the frame.

So what happens if you DONT do this correctly? The sweet spot will not be correct, the twisted bushing will want to return to its normal shape and effetely push the wheel down if you tightened with it hanging. This will make the ride a little more bouncy at times. And secondly, the bushing will fail quickly, because at normal ride height its being twisted.

Side note - if you are doing all this work, you may wont to do the strut rod bushings. A common failure point and having the front end apart will make them easier to do. Plenty of write-ups/nfo on those in the forum.

I have attached a pic of a Mark VIII lower arm. You can see the small teeth in the pic, I added some arrows. Also you can see some "teeth" at where the arm meets the frame.

So what happens if you DONT do this correctly? The sweet spot will not be correct, the twisted bushing will want to return to its normal shape and effetely push the wheel down if you tightened with it hanging. This will make the ride a little more bouncy at times. And secondly, the bushing will fail quickly, because at normal ride height its being twisted.

Side note - if you are doing all this work, you may wont to do the strut rod bushings. A common failure point and having the front end apart will make them easier to do. Plenty of write-ups/nfo on those in the forum.

I have to re read it so I can understand as I have not had the experience and familiar with the parts. This was excellent and well written and I will be sure to follow your tips as I want the best too. Right now I am still looking for a way to get the car up off the gravel. I am excited to get a new front end and new air ride . I have all new moog parts stored in my basement when the time comes. What kind of brand shocks did you put on your Mark? I liked the reason you like good rear shocks. Many thanksWith the front struts. Just hand tighten lower bowl at lower control arm. Then drop the front end down and air-up. To prevent a system fault, you may have to use the jacks initially to get the air-ride into a height window that wont cause an immediate fault. Once the car is at height, remove jacks and bounce it up and down gently to settle the suspension. Once its at or very close to ride height and things look good/level, tighten that lower bolt. Its a pain, because you can not lift the car to do them. Very long extensions help. You dont have to torque to spec though, just get as tight as you can so the bushing's teeth on its metal sleeve bite into the lower arm - enough that when you lift the front end back up they will not slip. Then you can tighten to spec. These same sorta teeth are found on most vehicle and most bushings. Its sorta acts as a secondary shock absorber, if that makes sense, to help get the suspension back to its sweet spot.

I have attached a pic of a Mark VIII lower arm. You can see the small teeth in the pic, I added some arrows. Also you can see some "teeth" at where the arm meets the frame.

So what happens if you DONT do this correctly? The sweet spot will not be correct, the twisted bushing will want to return to its normal shape and effetely push the wheel down if you tightened with it hanging. This will make the ride a little more bouncy at times. And secondly, the bushing will fail quickly, because at normal ride height its being twisted.

Side note - if you are doing all this work, you may wont to do the strut rod bushings. A common failure point and having the front end apart will make them easier to do. Plenty of write-ups/nfo on those in the forum.

View attachment 828569556

Ya know, I re read your message and it makes good sense. Being the mark is on the highway a lot keeping her up saves a lot of wear and tear.I agree with Unity. The system was designed to work often, meaning long lasting. They did design the system to lower/raisse for each hwy drive and build it accordingly.

For me I'm on and off the hwy 2 to 5 times a day. With having the ASHAM 8 module and my M8 at hwy height or a bit lower all the time there is no need for the system to lower the M8 further, so I installed the suspension switch in the interior (and turn it off before entering the hwy), it saves the system working those extra 2 to 5 times a day, thus the compressor would be used that much less and last longer.

unity

Dedicated LVC Member

I dont recall what I installed. It was soooo long ago. But I *think* they were a higher-end Monroe shock. Now days I would probably put on Bilstein touring or such. Honestly, you will notice a cheap shock over a good one more than you will the difference in brands at similar levels.

With the front struts. Just hand tighten lower bowl at lower control arm. Then drop the front end down and air-up. To prevent a system fault, you may have to use the jacks initially to get the air-ride into a height window that wont cause an immediate fault. Once the car is at height, remove jacks and bounce it up and down gently to settle the suspension. Once its at or very close to ride height and things look good/level, tighten that lower bolt. Its a pain, because you can not lift the car to do them. Very long extensions help. You dont have to torque to spec though, just get as tight as you can so the bushing's teeth on its metal sleeve bite into the lower arm - enough that when you lift the front end back up they will not slip. Then you can tighten to spec. These same sorta teeth are found on most vehicle and most bushings. Its sorta acts as a secondary shock absorber, if that makes sense, to help get the suspension back to its sweet spot.

I have attached a pic of a Mark VIII lower arm. You can see the small teeth in the pic, I added some arrows. Also you can see some "teeth" at where the arm meets the frame.

So what happens if you DONT do this correctly? The sweet spot will not be correct, the twisted bushing will want to return to its normal shape and effetely push the wheel down if you tightened with it hanging. This will make the ride a little more bouncy at times. And secondly, the bushing will fail quickly, because at normal ride height its being twisted.

Side note - if you are doing all this work, you may wont to do the strut rod bushings. A common failure point and having the front end apart will make them easier to do. Plenty of write-ups/nfo on those in the forum.

View attachment 828569556

Now I see what you did to avoid twisting the bushing. Putting some never sieze on the bolt that goes thru the bushing would make the rubber bush, especially the ends where frame touches bushing, slippery so the bushing could move around with no twisting? Could eleminate the second step and make it a one step to install. What do you think of idea , would it work?

unity

Dedicated LVC Member

No fantasize. You can put it on the bolt to prevent rusting internally. But it will do nothing for actual install. The bushing (see that pic above again) is essentially molded into a metal housing that is pressed into the arm. So off the bat, that bushing can not move. The "ears" of the strut go on each side and the bolt clamps it all together. So again, if you do it raised and you torque it down, the arm will raise relative to the strut and it will be twisted.

edit - think of it this way. Imagine if you had JUST the arm and JUST the strut on a work bench. If you dont tighten the bolt, the struts ears will be able to slide on over those teeth. Now tighten the bolt down to spec. Now if you tried to move the strut or arm, they will always want to return to the angle you tighten it down at. So if you tightened them at a 90 degree angle, so to speak, they will want to return to that even if you try all you can to make the strut near parallel to the arm.

edit - think of it this way. Imagine if you had JUST the arm and JUST the strut on a work bench. If you dont tighten the bolt, the struts ears will be able to slide on over those teeth. Now tighten the bolt down to spec. Now if you tried to move the strut or arm, they will always want to return to the angle you tighten it down at. So if you tightened them at a 90 degree angle, so to speak, they will want to return to that even if you try all you can to make the strut near parallel to the arm.

Hi Unity, Unity is a church well respected all over the usa and likely the world. Are you a unity member? Just re read yours,I Understand the rubber is molded to the steel bushing . The bushing with rubber is press fitted into the arm. That means the entire part will not move in the control arm. Now I can more understand what you patiently have been teaching me. I will like to talk more as I grasp what you say. Thanks Bill boats. P.s One nice thing is I can work in my garage at my pace with no time pressure. The garage is cluttered and that is important to clear it so the mark can be disabled inside .

Yes, Beyond twisting, the part cant move but increases resistance due to the ears and pushed the location back to the wrong angle unless the 2 step method is done . Great tip, a 5 star for you. Great pictures,Like the way you can show and explain the fine points to us other Mark guys. Bill boats . Just asked another question about interchangeability of suspension compressors for the board.Talk at you again

What I did was to use 20 patio stones 2'x3' (5 under each wheel) This made it easy to have the car at ride height and get under to torque the bolts to proper spec. Just keep the bolts loose, jack up the M8 and put the patio stones or alike under each wheel. Once the M8 is level and you have the normal ride height, torque the bolts and remove patio stones.Now I see what you did to avoid twisting the bushing. Putting some never sieze on the bolt that goes thru the bushing would make the rubber bush, especially the ends where frame touches bushing, slippery so the bushing could move around with no twisting? Could eleminate the second step and make it a one step to install. What do you think of idea , would it work?

Aside from the stones, did you first jack up the m8 before locating the car over patio stones? Then let the m8 bear its weight upon the patio stones?, Yesterday, I ordered via the phone with a live Arnott lady tech, 2 selenoids , s new bags, 1 new, not rebuilt, Arnott-Gast life time guarantee suspension compressor plug in play design, 2 new rear air bags, also life time warrantee. The rear shocks I have a choice of Monroe oes spectrum shock, fits 1996 thunderbird, and will fit the 96M at 36.49 each, or the KYG most expensive passenger shock advanced sells at 46.99 each , a gas shock with hydraulic features, . With on line discount the Monroes a pair are 57.00. . The KYB's are 74.92, just 17.92 more however, the lower priced are the Monroes spectrum gas , the shocks you vaguely remember installing on your M*. Can you remember exactly what Monroe shock you have now on your M*. Did you ever know anything about the KYB shocks? they are more expensive). Compair to Arnott shocks at 149.00 a pair, these are bargains. Would you but KYB if you had it to do over again?

Last edited:

nice comment.I think you will be happy once all is done.