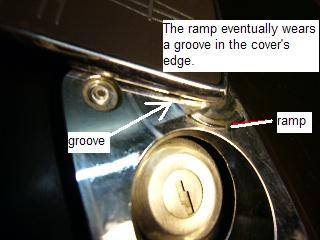

My key cover plate was worn on it's edge, from thousands of openings over the years. The cover would not stay up and out of the way of the key, so it took two hands to insert a key. It is designed to be caught by the top edge of the tapered "ramp". (see pix)

The wear can't be repaired by welding or soldering because it's a zinc pot metal and would be destroyed by high heat. So would the plastic emblem..

This is how I fixed mine. You might think of a better or easier way... and more power to you.

------------

Lincoln was kind enough to use soft aluminum rivets on mine.

First drill out/off the plate's 2 attaching rivets' heads with a 3/16" (or so) drill bit. The head will likely "spin" and you'll know you've cut through and drilled deep enough. Needless to say, don't drill deeper than necessary... so I say it anyway.

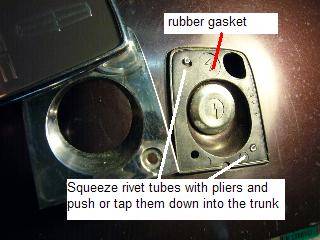

The rivets' bodies might then fall into the trunk. If not, squeeze the remainder of the protruding tubes, and gently tap them in with a skinny "nail set" or a nail or something.

The plate and cover will come off. That's all that needs to be removed. The lock and all that stuff stays where it is.

----------

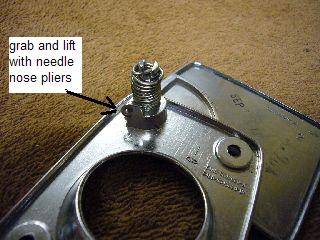

Flip it over and see that the cover plate is attached by a strong spring. Grab the spring's lower hook end with a pliers and lift it a little to release the hook. Then turn the spring to release it's top "S" shape. Needless to say, don't let the spring fly away into Never-Never land... so I say it anyway.

The two pieces can be separated.

The wear can't be repaired by welding or soldering because it's a zinc pot metal and would be destroyed by high heat. So would the plastic emblem..

This is how I fixed mine. You might think of a better or easier way... and more power to you.

------------

Lincoln was kind enough to use soft aluminum rivets on mine.

First drill out/off the plate's 2 attaching rivets' heads with a 3/16" (or so) drill bit. The head will likely "spin" and you'll know you've cut through and drilled deep enough. Needless to say, don't drill deeper than necessary... so I say it anyway.

The rivets' bodies might then fall into the trunk. If not, squeeze the remainder of the protruding tubes, and gently tap them in with a skinny "nail set" or a nail or something.

The plate and cover will come off. That's all that needs to be removed. The lock and all that stuff stays where it is.

----------

Flip it over and see that the cover plate is attached by a strong spring. Grab the spring's lower hook end with a pliers and lift it a little to release the hook. Then turn the spring to release it's top "S" shape. Needless to say, don't let the spring fly away into Never-Never land... so I say it anyway.

The two pieces can be separated.