You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sport 16mm front knuckle availability?

- Thread starter Broseph

- Start date

ajv8

Well-Known LVC Member

just buy a 14mm ball jointI just discovered that my car has the 14mm stud, not the 16mm. Can I just ream the hole in my lower control arm to 16mm?

theophile

Well-Known LVC Member

Well yeah, but where's the fun in that?just buy a 14mm ball joint

Just slap on a ford 14mm they are still availableWell yeah, but where's the fun in that?

04_Sport_LS

Dedicated LVC Member

Can I just ream the hole in my lower control arm to 16mm?

I would not do that. You have no way of gauranteeing concentricity... and would have a hard time getting the proper taper.

Keep in mind that the stud "wedge fits" into the control arm. That's what keeps the ball joint from spinning in the hole.

So what I’m hearing is owners with a sport LS are stuck with pressing in new ball joints, or rolling the dice with an aftermarket knuckle assembly?

If so, what brand ball joint? I can attest that Moog is not a good brand like they were a decade ago with my two failed joints.

If so, what brand ball joint? I can attest that Moog is not a good brand like they were a decade ago with my two failed joints.

theophile

Well-Known LVC Member

It's not sport, is it? I thought the 14mm to 16mm switch happened for all models part way through the 2002 model year. Mine's a sport but according to FPG has the 14mm studs. Meanwhile I took 16mm studs off an '02 base V6 yesterday.

04_Sport_LS

Dedicated LVC Member

Gen 1 LS... 1999-2002 14mm ball joint.

Gen 2 LS... 2003-2006 16mm ball joint.

Sport/non-Sport... doesn't matter. Just year. (date of manufacture)

Could be some cross over months during mamufacture but not sure. Contact dealer with VIN number to verify ball joint size.

Gen 2 LS... 2003-2006 16mm ball joint.

Sport/non-Sport... doesn't matter. Just year. (date of manufacture)

Could be some cross over months during mamufacture but not sure. Contact dealer with VIN number to verify ball joint size.

Gen 1 LS... 1999-2002 14mm ball joint.

Gen 2 LS... 2003-2006 16mm ball joint.

Sport/non-Sport... doesn't matter. Just year. (date of manufacture)

Could be some cross over months during mamufacture but not sure. Contact dealer with VIN number to verify ball joint size.

Interesting. I could’ve sworn there was something else suspension wise besides the shocks that the sport had.

Guess I just assumed all sports had 16mm because I do. I have a Nov 2002 production date so that would make sense with the mid-year changes that happened in July.

04_Sport_LS

Dedicated LVC Member

I could’ve sworn there was something else suspension wise besides the shocks that the sport had.

Larger sway bars. Springs are slightly stiffer too.

04_Sport_LS

Dedicated LVC Member

I have a Nov 2002 production date so

That means you have a 2003 LS.

July or August is typically when the manufacture years roll over.

I know my LSs and she’s most definitely not an 03. I just don’t know manufacturing dates apparently

Not sure why November came to mind, I felt certain, but door tag says June. Now Im curious and want to check my VIN for exact date.

Which I suppose June would be close enough to the 03 production run for the 16mm joints.

Not sure why November came to mind, I felt certain, but door tag says June. Now Im curious and want to check my VIN for exact date.

Which I suppose June would be close enough to the 03 production run for the 16mm joints.

04_Sport_LS

Dedicated LVC Member

can attest that Moog is not a good brand like they were a decade a

Not exactly true. Moog has 2 series of suspension parts (for ball joints, tie rods etc). The "K" series is the premium parts.

04_Sport_LS

Dedicated LVC Member

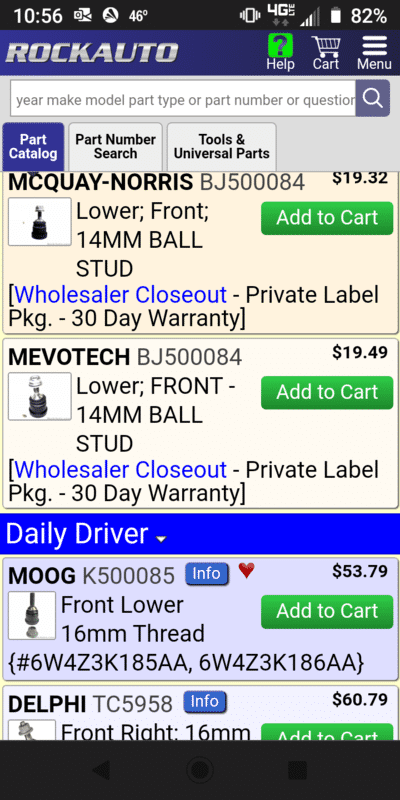

Did a search on RA for '03 LS ball joint. It shows both 14mm and 16mm.

The Mcquay Norris should be a good joint for the 14mm.

The Moog or Delphi should be good for the 16mm.

The Mcquay Norris should be a good joint for the 14mm.

The Moog or Delphi should be good for the 16mm.

While I like the Harbor Freight ball joint kit I found it did not fit a lot of cars/trucks. Just not enough adapters to fit everything. Don't know if you have seen it but they also sell a kit of JUST adapters to go with the ball joint press kit. Not bad at $55 and now you do have a very wide range of adapters to use.

The bad thing is it now shows clearance which means they are dropping it. Hope they come out with another one probably with a different brand name as it seems they are in a massive upgrade of their tools.

I think the video showed the key. Don't use a press. Use a ball joint tool. It aligns things much better to prevent damage.

.

.

.

The bad thing is it now shows clearance which means they are dropping it. Hope they come out with another one probably with a different brand name as it seems they are in a massive upgrade of their tools.

I think the video showed the key. Don't use a press. Use a ball joint tool. It aligns things much better to prevent damage.

.

.

.

04_Sport_LS

Dedicated LVC Member

Probably on clearance because just like the LS... most cars today have aluminum suspension components that are not intended to be serviceable... and they want people to buy the whole suspension component. (control arm or knuckle)

theophile

Well-Known LVC Member

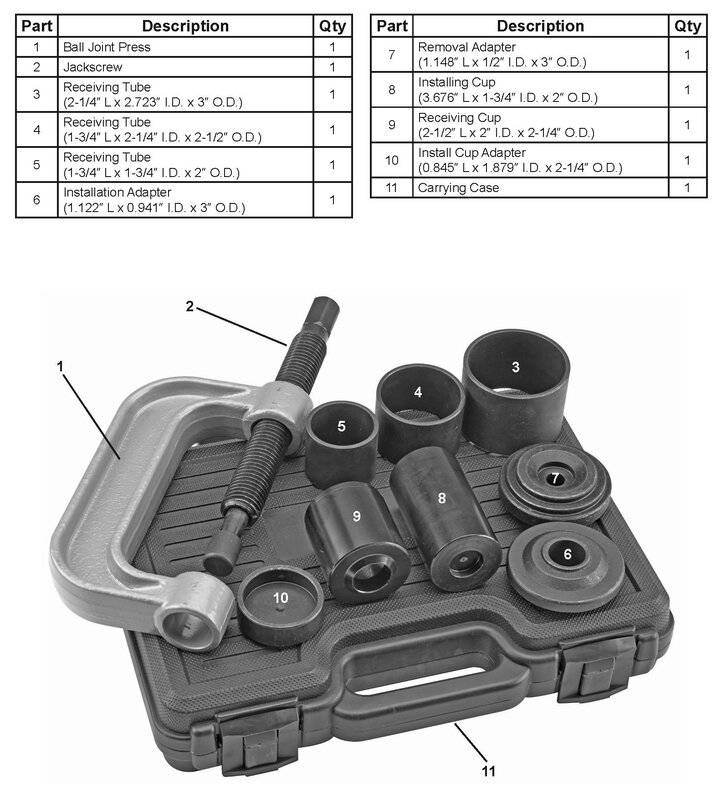

So, first impressions trying to replace the lower ball joints of the LS using the Harbor Freight "Maddox" ball joint press kit. Here again is the contents list for reference:

The #4 receiving cup does indeed fit perfectly over the "back" of the ball joint for removal purposes. However, because it is merely a cylinder, you need to use the #6 adapter between the back of the C-clamp and the #4 receiving cup. And since the #6 adapter has a larger diameter than the #4 receiving cup, the knuckle doesn't leave enough clearance for the #6 adapter to sit perfectly center on the #4 receiving cup. That said, I have figured out that I can get it to sit flush against the receiving cup, though slightly off-center. I think that should probably be OK for removal purposes, although for installing the new ball joint, you definitely want the driving force to be dead center.

Ideally, you would want to receiving cup that has the same dimensions as the #4 cup in the Maddox kit, but that also has the raised mating surface to use the with C-clamp without an adapter. In other words, something like the #9 cup pictured above but with the diameter of the #4 cup.

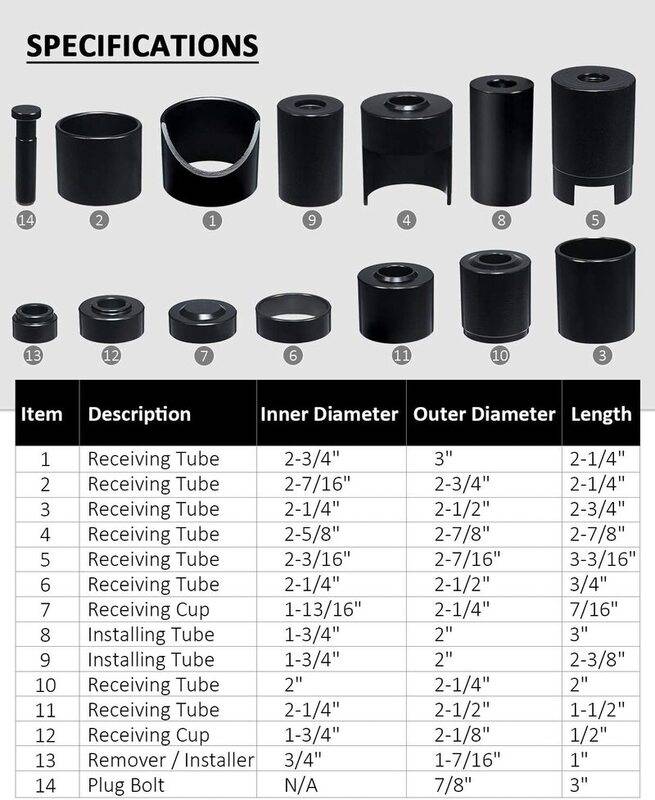

I am considering purchasing this 14-piece adapter kit from Orion, which looks like it's the same set as the now-discontinued Pittsburgh Automotive set that Harbor Freight used to sell. Here's the contents list for it:

According to this, the #11 receiving cup has an inner diameter of 2.25" just like the Maddox #4, but as shown in the picture, it's got the raised mating surface to use with the C-clamp without an adapter. It's also 1/4" shorter, which leads me to the next issue I ran into.

Although I think it's possible to remove the ball joints with just the Maddox kit if you line everything up just right, I've concluded that it's not possible to do it without cutting the stud off the ball joint because the various adapters you have to use end up being too long to fit in the C-clamp. I tried pressing against the end of the stud but it became clear that things would not stay lined up doing it this way. If you cut the stud off as shown in the video on the previous page, you can press against the joint with much less risk of things going out of alignment. I haven't tried this yet though because I need to get some cut-off wheels for my angle grinder to actually cut the stud off.

For installation, it looks like it should be possible to install the new ball joints with just the Maddox kit, assuming you put the "back" of the C-clamp directly against the back of the new ball joint. You can then stack the tubes as needed to press in the new ball joint. I haven't gotten to this stage yet though so I'm sure something will come up to complicate things (something always does!).

I will say though that the Maddox ball joint kit has been very helpful for replacing control arm bushings! It was actually quite easy to press out old rear-lower bushings and press in the new Powerflex ones, except of course for the bushing with the metal sleeve that you have to cut out!

I'll try to update once I make another attempt.

The #4 receiving cup does indeed fit perfectly over the "back" of the ball joint for removal purposes. However, because it is merely a cylinder, you need to use the #6 adapter between the back of the C-clamp and the #4 receiving cup. And since the #6 adapter has a larger diameter than the #4 receiving cup, the knuckle doesn't leave enough clearance for the #6 adapter to sit perfectly center on the #4 receiving cup. That said, I have figured out that I can get it to sit flush against the receiving cup, though slightly off-center. I think that should probably be OK for removal purposes, although for installing the new ball joint, you definitely want the driving force to be dead center.

Ideally, you would want to receiving cup that has the same dimensions as the #4 cup in the Maddox kit, but that also has the raised mating surface to use the with C-clamp without an adapter. In other words, something like the #9 cup pictured above but with the diameter of the #4 cup.

I am considering purchasing this 14-piece adapter kit from Orion, which looks like it's the same set as the now-discontinued Pittsburgh Automotive set that Harbor Freight used to sell. Here's the contents list for it:

According to this, the #11 receiving cup has an inner diameter of 2.25" just like the Maddox #4, but as shown in the picture, it's got the raised mating surface to use with the C-clamp without an adapter. It's also 1/4" shorter, which leads me to the next issue I ran into.

Although I think it's possible to remove the ball joints with just the Maddox kit if you line everything up just right, I've concluded that it's not possible to do it without cutting the stud off the ball joint because the various adapters you have to use end up being too long to fit in the C-clamp. I tried pressing against the end of the stud but it became clear that things would not stay lined up doing it this way. If you cut the stud off as shown in the video on the previous page, you can press against the joint with much less risk of things going out of alignment. I haven't tried this yet though because I need to get some cut-off wheels for my angle grinder to actually cut the stud off.

For installation, it looks like it should be possible to install the new ball joints with just the Maddox kit, assuming you put the "back" of the C-clamp directly against the back of the new ball joint. You can then stack the tubes as needed to press in the new ball joint. I haven't gotten to this stage yet though so I'm sure something will come up to complicate things (something always does!).

I will say though that the Maddox ball joint kit has been very helpful for replacing control arm bushings! It was actually quite easy to press out old rear-lower bushings and press in the new Powerflex ones, except of course for the bushing with the metal sleeve that you have to cut out!

I'll try to update once I make another attempt.

theophile

Well-Known LVC Member

So I got the Orion 14-piece adapter set to complement the Harbor Freight ball joint press. It works great! I used the #11 receiving cup from the Orion kit for removal of the old ball joint and the #5 tube from the Orion kit for installation of the new ball joint.

I also figured out a neat trick for removing the old ball joint without having to cut off the stud. Here's the knuckle in the vice with the old ball joint in it:

The forcing screw for the ball-joint press has a "plug" at the end of it that seats inside of an indentation on the installation tubes to keep things lined up. But you can just pull that plug out. There's a rubber o-ring inside, and also a ball bearing that you can carefully remove. Once you've done that, the "business end" of the forcing screw is hollow:

At it happens, this is plenty wide and deep enough for the stud to sit all the way inside:

So you can line up the press with the receiving tube on the back, and then thread the forcing screw into the C-clamp until it bottoms out against the tapered flange of the ball joint:

At this point, I just used a 1/2" drive ratchet with an 18" extending handle and pressed out the ball joint a quarter turn at a time. No impact wrench, not even a breaker bar. Then I used some 800-grit sandpaper and PB Blaster to clean out the hole and surrounding area.

I already had the new ball joints in the deep freeze overnight just to help make things a little easier. It was just a matter of lining up the new ball joint against the back of the C-clamp, and then using the #5 receiving tube from the Orion kit against the forcing screw (with the ball bearing, O-ring, and "plug" reinstalled, of course) to press in the new one. The back of the C-clamp does not "seat" itself with respect to the ball joint, so I had to make sure the clamp was lined up and sitting flush against the back of the ball joint housing, and then hand tightened the forcing screw to keep pressure on everything while I double checked alignment. Then, before starting to press in the new ball joint, I sprayed it down really good with PB Blaster. Then I just turned it in slowly and carefully, a quarter turn at a time:

It went in nice and smooth!

I did both of them in about 30 minutes. I could do it faster if I had to do it again, but wanted to make sure to do it slowly and carefully so as not to risk damaging the aluminum.

One important note though: Although the donor knuckles came off a car with 16mm ball joints, my car uses the 14mm ball joints so that's what I was installing. The studs on the 14mm ball joints are shorter than on the 16mm joints. So while the #5 installation cup from the Orion set worked perfectly for installing the 14mm ball joints, that cup isn't quite deep enough for the stud on the 16mm ball joint. If you're installing the 16mm ball joints, you can start the installation the same way and get the new ball joint part way in, but once you start feeling increased resistance, you need to stop turning the screw and back it off, or else you're just compressing the new ball joint and will risk damaging it. At that point, you'll need to experiment with the other adapters to find a combination that works to finish pressing the new joint the rest of the way in.

EDIT: Actually, I double checked, and even for the 16mm ball joints, MOOG makes the stud shorter than on the stock ball joint, presumably for this very reason. As you can see below, the distance between the mating flange and the tip of the stud is shorter on the 16mmm MOOG (left) than on the stock 16mm ball joint (right):

So if you're installing MOOGs, you can use the #5 installation cup from the Orion kit to press in the new ones all the way, regardless of whether you're installing 14mm or 16mm.

I also figured out a neat trick for removing the old ball joint without having to cut off the stud. Here's the knuckle in the vice with the old ball joint in it:

The forcing screw for the ball-joint press has a "plug" at the end of it that seats inside of an indentation on the installation tubes to keep things lined up. But you can just pull that plug out. There's a rubber o-ring inside, and also a ball bearing that you can carefully remove. Once you've done that, the "business end" of the forcing screw is hollow:

At it happens, this is plenty wide and deep enough for the stud to sit all the way inside:

So you can line up the press with the receiving tube on the back, and then thread the forcing screw into the C-clamp until it bottoms out against the tapered flange of the ball joint:

At this point, I just used a 1/2" drive ratchet with an 18" extending handle and pressed out the ball joint a quarter turn at a time. No impact wrench, not even a breaker bar. Then I used some 800-grit sandpaper and PB Blaster to clean out the hole and surrounding area.

I already had the new ball joints in the deep freeze overnight just to help make things a little easier. It was just a matter of lining up the new ball joint against the back of the C-clamp, and then using the #5 receiving tube from the Orion kit against the forcing screw (with the ball bearing, O-ring, and "plug" reinstalled, of course) to press in the new one. The back of the C-clamp does not "seat" itself with respect to the ball joint, so I had to make sure the clamp was lined up and sitting flush against the back of the ball joint housing, and then hand tightened the forcing screw to keep pressure on everything while I double checked alignment. Then, before starting to press in the new ball joint, I sprayed it down really good with PB Blaster. Then I just turned it in slowly and carefully, a quarter turn at a time:

It went in nice and smooth!

I did both of them in about 30 minutes. I could do it faster if I had to do it again, but wanted to make sure to do it slowly and carefully so as not to risk damaging the aluminum.

EDIT: Actually, I double checked, and even for the 16mm ball joints, MOOG makes the stud shorter than on the stock ball joint, presumably for this very reason. As you can see below, the distance between the mating flange and the tip of the stud is shorter on the 16mmm MOOG (left) than on the stock 16mm ball joint (right):

So if you're installing MOOGs, you can use the #5 installation cup from the Orion kit to press in the new ones all the way, regardless of whether you're installing 14mm or 16mm.

Last edited:

04_Sport_LS

Dedicated LVC Member

already had the new ball joints in the deep freeze overnight just to help make things a little easier.

Smart move.

Actually, I double checked, and even for the 16mm ball joints, MOOG makes the stud shorter than on the stock ball joint, presumably for this very reason.

...and there is an internal hex +,(instead of external) to hold the ball joint stud when tightening the nut.