Fleetwood86

LVC Member

Specs:

1994 Lincoln Continental - Executive Series

Looking for OEM Bypass Heater Hose part number F10H18D334.

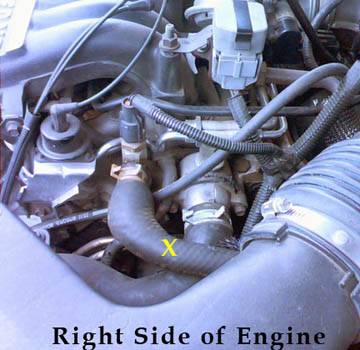

This is the hose that begins at the manifold and meanders to firewall to hook onto the Temperature Control Lockout Switch.

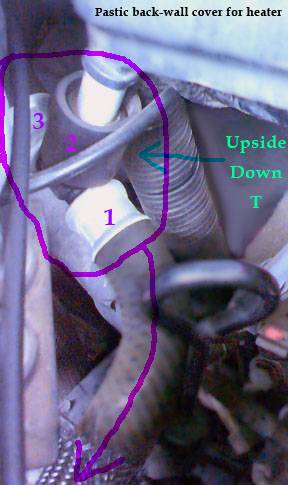

Note in the picture that the OEM hose has the factory installed large metal clamp to secure it to the switch. I have the claim marked as #1 on the upside down T shaped switch.

While there are comperable hoses, none come with the large clamp.

I am told that Master Craft was the original vendor that made the part for Ford/Lincoln. I found a web site where they sell a replica of the part number but it does not have the large metal clamp.

Any suggestions would be appreciated if anyone had to make their own clamp, or, where to find a clamp. I've checked with the local auto parts store and they have nothing even close. I also checked a few repair shops specializing in radiators and hoses, and they said to go to the dealership, etc.

1994 Lincoln Continental - Executive Series

Looking for OEM Bypass Heater Hose part number F10H18D334.

This is the hose that begins at the manifold and meanders to firewall to hook onto the Temperature Control Lockout Switch.

Note in the picture that the OEM hose has the factory installed large metal clamp to secure it to the switch. I have the claim marked as #1 on the upside down T shaped switch.

While there are comperable hoses, none come with the large clamp.

I am told that Master Craft was the original vendor that made the part for Ford/Lincoln. I found a web site where they sell a replica of the part number but it does not have the large metal clamp.

Any suggestions would be appreciated if anyone had to make their own clamp, or, where to find a clamp. I've checked with the local auto parts store and they have nothing even close. I also checked a few repair shops specializing in radiators and hoses, and they said to go to the dealership, etc.

Last edited: