unclemuck

LVC Member

Hi All;

This post will outline how I went about rebuilding my seat motors, going from having only lumbar and recline in both the front seats, to every axis working correctly. A good project for this time, where many of you are at home, and might have a few days to do it, and don't have to rush if you're not needing to drive the same day. I'll give the full story so you have as much information as possible. Your mileage may vary, and maybe you'll find a better way to do some of the disassembly, as I did it on a whim with little knowledge of how it would turn out, and no guidance on how to the seat, gears, tubes and connections all fit together, much less came apart, or if it was even possible, as the manual just says 'Replace seat track' when a motor is bad. It's not terribly difficult, but the disassembly is awkward, you have to figure out the right way to take things apart, move things out of the way in order to reach other parts, etc. A bit like a puzzle. Some organizational discipline and a good sized area of floor will come in handy. I just took the entire seats out, tipped them back, and worked that way.

Before we get started, here is a bonus: There are model years of the Ford Escape (I believe) and a few others, possible the MKZ, that share the same heated-seat fan. I was able to also recently replace one for a grand total of $5-10 at the local yard. Much better than the other one I bought off ebay for something like $60.

Bonus #2: I could be wrong on the models above (can't remember where I got what), but some of those also share the same lock actuator motors - albeit some with slightly different mechanical linkages, but I was also able to pull out the motor and gear from one of those, for another $5-10 repair when one of mine failed. Got lucky the girl at the checkout had no idea what it was, otherwise would have been probably $25.

Now this will only work if you have the same issue as mine; My symptoms were that the motors didn't work at all, the solenoids clicked, but no movement what-so-over, (one of them I could maybe feel the motor getting energized and torquing up, but was bound and couldn't actually rotate) and a couple codes regarding vertical and horizontal position sensors. Tried re-calibrating multiple times, and still nothing. Checked fuses, etc. So I was pretty sure everything else was good, and it was likely the motors themselves that were somehow borked.

Here's an overall summary of how it went down:

Ever since I bought my LS last May, the only motors that worked were the lumbar, and seat-back. It also had a leak from the moon-roof that likely went un-repaired for quite some time, and I believe this to be a major factor in the failing of both the seat motors and heated-seat fans.

It was getting more and more annoying, as I always had to apologize to my front-seat passengers as the seat was stuck all the way forward, and also had not heat. I had been looking online to find replacement seats, but wasn't looking forward to the cost and possible work involved with removing the covers and transplanting.

I finally found a reasonably priced passenger seat frame on ebay (~$90 or so), that came with all the motors and even a heated seat fan that looked good. It arrived, took the bottom frame off (as I didn't need to go through the trouble of the seat back where the recline and lumbar already worked), installed it, and to my dismay, only one of the two motors actually worked, and the heated seat fan was terribly noise.

At this point I was frustrated, but was able a partial refund on the seat. Now I had an extra seat track and motors, so I thought to myself, what the hell, I'll take some of the motors apart and see what's in there, and see how hard they are to get off the frame. Wasn't too bad, and learned a few things, so pulled the driver's seat out, for the first live-patient surgery.

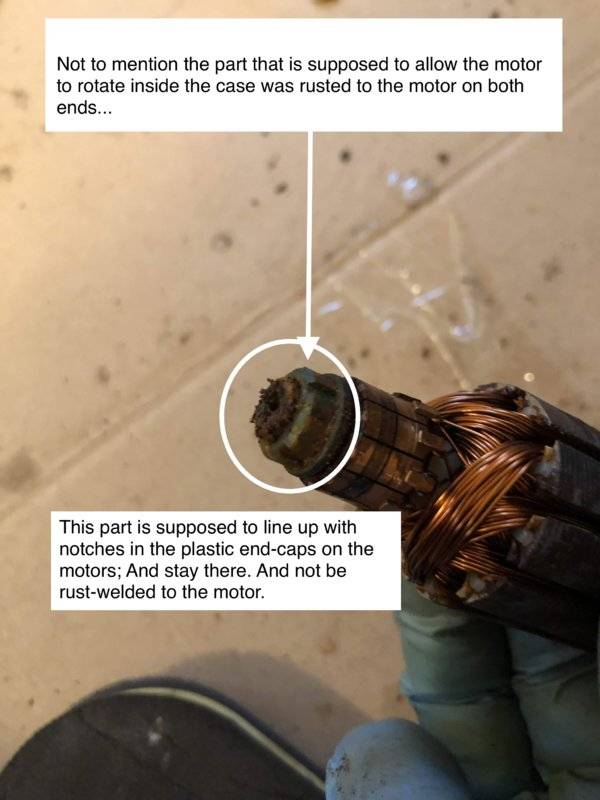

It turned out that the springs that pushed the brushes into the motor contacts were completely rusted into globs, along with the motor guide that is supposed to allow the motor to spin inside the case, being totally rusted to the motor. I took them all apart, completely apart, replaced the springs, cleaned out all the rust, cleaned and lubricated everything that was supposed to move (some parts were so bad I had to use high-grit sandpaper to get them reasonably smooth), lubricated the worm screws, put it back together, said a prayer to the seat motor gods, re-activated the airbag system, re-calibrated - et voila! Wouldn't you know it, the damned things worked. It took a couple re-calibrations to work through some of the grit and such to get the full travel, but eventually the full range was available and consistent. On one of the seats, one of the motors initially didn't work, so in frustration, I spammed the seat control up-down-up-down-up-down for probably 15 seconds, which miraculously loosened something up, and it began working, and hasn't stopped since.

I apologize, I thought I had taken more pictures when documenting, but looking back it wasn't that many; probably because my gloves were covered in rust and grease for most of the endeavor. I tried to annotate the pictures as well as I could after-the-fact, but let me know if I can clear anything else up. I still have the extra seat frame, and a couple extra motors, so if you need parts, or more pictures with explanation, maybe I can help.

OK; now that the story is out of the way, on to the repair with pictures.

====================

!!! IMPORTANT: !!!

====================

First, follow the repair manual with regard to de-powering / activating the airbag system, and how to remove the seats.

NOTE:

Go slow and take your time. Label things if you want. Do one motor at a time if you want. Don't rush it, getting frustrated will make it harder.

NOTE:

There are steel cables that go through the ends of the motors, and go into the gearboxes. They have square tips, but are mostly round. The square tip goes into the square receiver on the motor shaft. And one long cable through the torque tube attached to the horizontal motor. The torque tube rotates and will come off, but it's awkward.. you'll see.. The cables pull straight out of the motor shafts, and can be tricky to fit back into place sometimes. See next note...

NOTE:

The torque tube on the horizontal motor is a bitch. Seemed to be much harder to put back in than it was to take apart. Let's just say I had to bend it way more than I thought when trying to get it back in place. I really thought it was going to snap multiple times, or that I wasn't going to be able to put it back together. Just keep futzing with it, but be cautious at the same time, and don't snap it.

NOTE:

The steel cables that connect the motors to the gearboxes just pull straight out. Same thing with the one in the torque tube, it's just much longer. And a huge pain.

---------------------------------------------------

Tools:

---------------------------------------------------

Basic hand tools, screw drivers, pliers, etc. of various sizes

Torx T25 (gearboxes)

Small springs - the cheap assortment package from Lowes has some of about the right size, plus then you'll have like 50 extra springs to keep around. But I'm sure you can get some individually, sourced retail or from other things you have laying around.

Lubricant (I used white lithium mostly)

Brush for removing rust (I used a small brass brush)

Possibly some high-grit sandpaper, and/or fine steel wool

You will probably need a small ratcheting 90* screwdriver, (or bits for a 1/4 ratchet), for trying to get a screw into or out of the motor cases - very little clearance, and sometimes you're doing it by feel, which is made worse by the fact the motor magnets are pulling the screw out of alignment while you're also trying to hold all the pieces of the motor together...

---------------------------------------------------

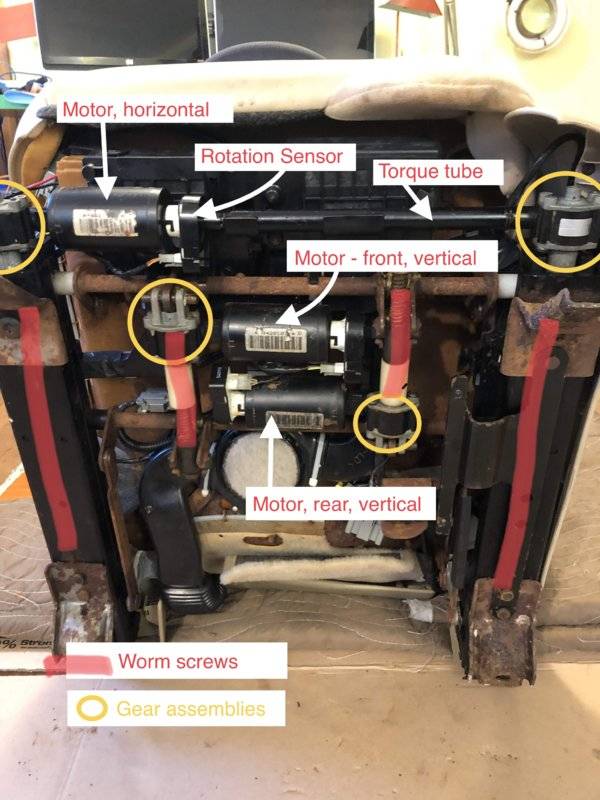

1) Bottom-view of the driver's seat:

---------------------------------------------------

---------------------------------------------------

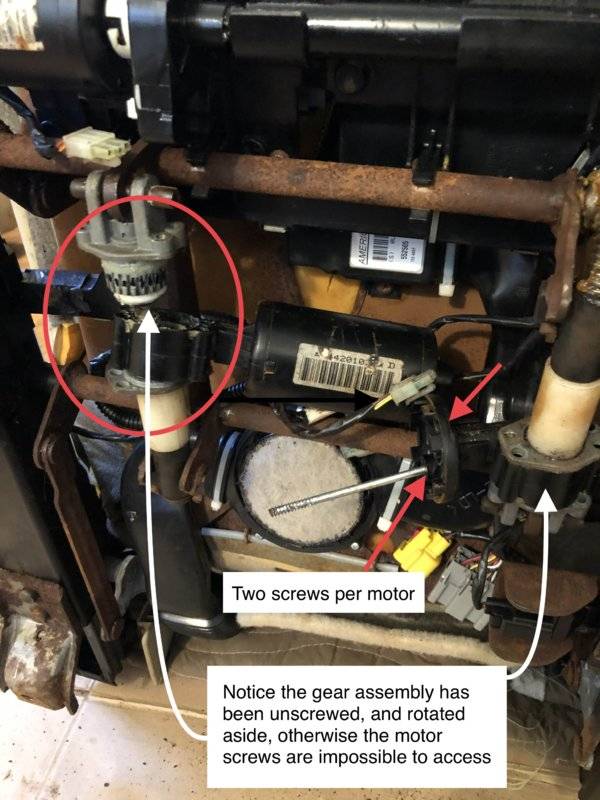

2) Removing the gear assembly from motor:

---------------------------------------------------

First, remove the electrical connectors from the motors. Then remove the motor from the gearbox assembly.

I found the best/only? way to get to the back of the motors so you can take them out, is to first remove the screws (T25) from the gearboxes first, then you can slide it up off the worm gear, and be able to rotate the motor so you can actually get at the screws on the back of it.

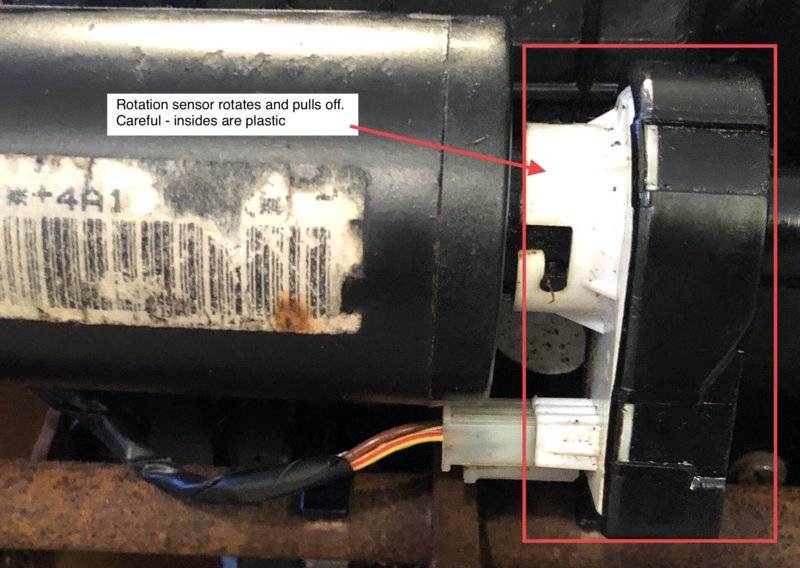

You may or may not be able/have to remove the rotations sensors at this step as well, I don't remember; Just be careful, they are totally plastic. You can see in the next pictures how they rotate, un-clip, and then just pull off of the square cable that goes into the motor.

^ Notice there is one screw for the aft vertical motor still in the mount - I think this one physically did not have enough clearance to be pulled out completely...

---------------------------------------------------

3) Motor disassembly

---------------------------------------------------

Once a motors is out, you can pull the case off (it's magnetic, and will get attracted to the motor, but it comes off). Then you might see something like this...

Yea that's not what it's supposed to look like.

---------------------------------------------------

3) Motor cleaning

---------------------------------------------------

NOTE:

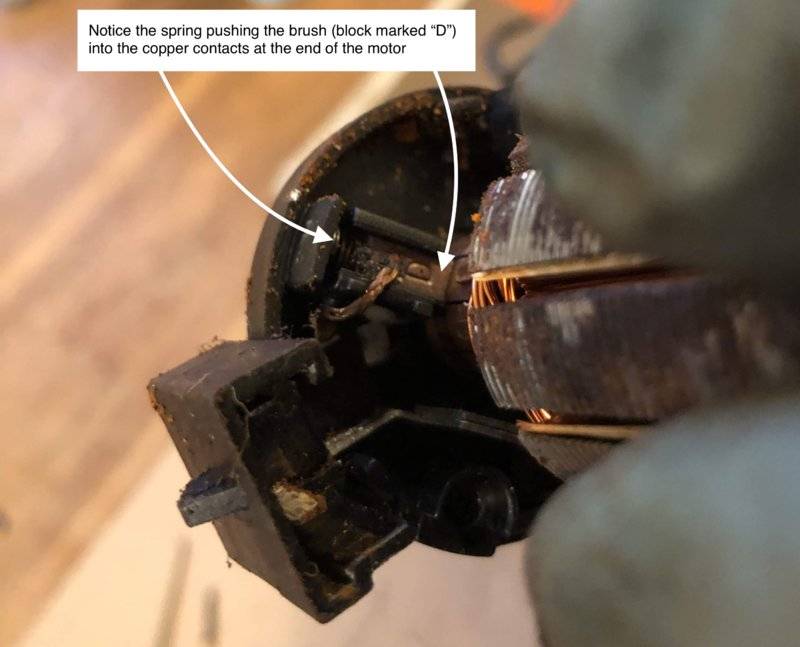

Brushes are being pushed into the motor contact with springs. Be careful they don't fly out when you remove the motor.

NOTE:

There are braided wires going to the brushes. The brushes are supposed to slide in their slots to keep pressing against the copper contacts - as they get used and the brushes are worn, they continue to make contact.

Even as bad as these were, I didn't have to re-solder the braid, but be careful or you might.

I wish I took more pictures for these steps, sorry - maybe I can upload some after-the-fact.

What you will do here, is pull the motor out of the plastic mount. It should just pull straight out. Just be mindful that the springs don't go flying if the aren't held in by gunk, or whatever tab or item they were supposed to be attached held in with in the first place.

Once the motor is out, then you can slide the brushes out of their slots, clean the slots, clean the brush, replace a spring, etc.

I had to replace a spring on each of mine; I happen to have packages or misc sized springs that worked out well, but you may have luck even with a spring from a pen, and can cut it if you need to. Just try to match or get close to one of the good ones in size and compression.

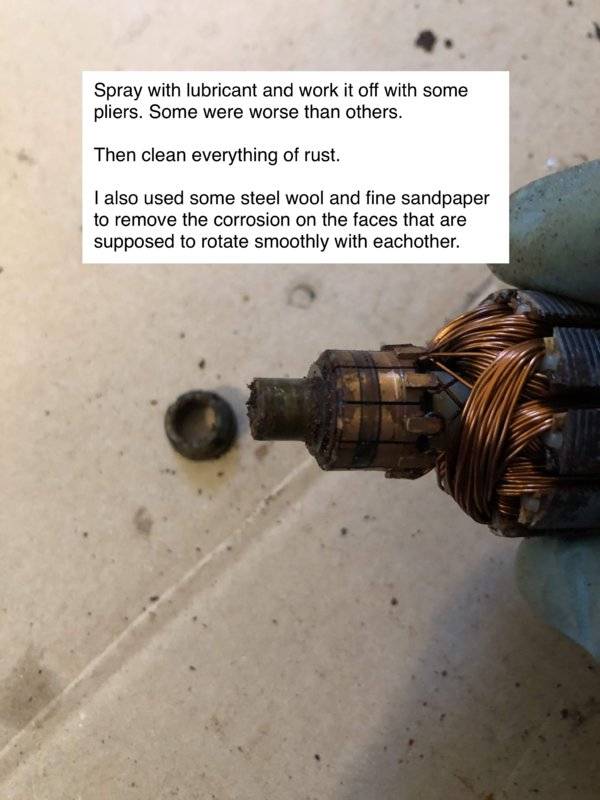

Then, you should clean the metal inserts that are inside each end of the motor case, and make sure they are smooth inside. Also clean the motor shaft that rotates inside of this piece. Should look something like this when you're done:

---------------------------------------------------

4) Reassembly

---------------------------------------------------

Once everything is clean, you can start to put everything back together. Essentially reversing the steps you took when taking it apart.

NOTE:

Make sure to line the motor case up correctly, with the notches. It will be awkward to get the screws back in, as they will be attracted to the magnets in the case. Just keep fiddling with it until it goes in right.

Once all the motors are assembled (easier said than done, I know, again, sorry for the lack of pictures), then put the gearboxes back together, and the electrical connections back on the motors.

Follow the service manual for replacing the seat, and re-powering/activating the SRS system.

Don't be discourages if they don't immediately work; I had to run a few calibrations, and kinda work the seat controls a few times before they all worked. But then again, the corrosion I experienced will probably be worse than yours, the car was sitting for a little while with a leaky moon-roof before I got it.

That should be it, and if you're like me, you can now do the whole thing over again with the other seat! Much easier the second time around, after you figured out how things move around and go together.

Good luck, and let me know if there is anything I can explain in more detail.

This post will outline how I went about rebuilding my seat motors, going from having only lumbar and recline in both the front seats, to every axis working correctly. A good project for this time, where many of you are at home, and might have a few days to do it, and don't have to rush if you're not needing to drive the same day. I'll give the full story so you have as much information as possible. Your mileage may vary, and maybe you'll find a better way to do some of the disassembly, as I did it on a whim with little knowledge of how it would turn out, and no guidance on how to the seat, gears, tubes and connections all fit together, much less came apart, or if it was even possible, as the manual just says 'Replace seat track' when a motor is bad. It's not terribly difficult, but the disassembly is awkward, you have to figure out the right way to take things apart, move things out of the way in order to reach other parts, etc. A bit like a puzzle. Some organizational discipline and a good sized area of floor will come in handy. I just took the entire seats out, tipped them back, and worked that way.

Before we get started, here is a bonus: There are model years of the Ford Escape (I believe) and a few others, possible the MKZ, that share the same heated-seat fan. I was able to also recently replace one for a grand total of $5-10 at the local yard. Much better than the other one I bought off ebay for something like $60.

Bonus #2: I could be wrong on the models above (can't remember where I got what), but some of those also share the same lock actuator motors - albeit some with slightly different mechanical linkages, but I was also able to pull out the motor and gear from one of those, for another $5-10 repair when one of mine failed. Got lucky the girl at the checkout had no idea what it was, otherwise would have been probably $25.

Now this will only work if you have the same issue as mine; My symptoms were that the motors didn't work at all, the solenoids clicked, but no movement what-so-over, (one of them I could maybe feel the motor getting energized and torquing up, but was bound and couldn't actually rotate) and a couple codes regarding vertical and horizontal position sensors. Tried re-calibrating multiple times, and still nothing. Checked fuses, etc. So I was pretty sure everything else was good, and it was likely the motors themselves that were somehow borked.

Here's an overall summary of how it went down:

Ever since I bought my LS last May, the only motors that worked were the lumbar, and seat-back. It also had a leak from the moon-roof that likely went un-repaired for quite some time, and I believe this to be a major factor in the failing of both the seat motors and heated-seat fans.

It was getting more and more annoying, as I always had to apologize to my front-seat passengers as the seat was stuck all the way forward, and also had not heat. I had been looking online to find replacement seats, but wasn't looking forward to the cost and possible work involved with removing the covers and transplanting.

I finally found a reasonably priced passenger seat frame on ebay (~$90 or so), that came with all the motors and even a heated seat fan that looked good. It arrived, took the bottom frame off (as I didn't need to go through the trouble of the seat back where the recline and lumbar already worked), installed it, and to my dismay, only one of the two motors actually worked, and the heated seat fan was terribly noise.

At this point I was frustrated, but was able a partial refund on the seat. Now I had an extra seat track and motors, so I thought to myself, what the hell, I'll take some of the motors apart and see what's in there, and see how hard they are to get off the frame. Wasn't too bad, and learned a few things, so pulled the driver's seat out, for the first live-patient surgery.

It turned out that the springs that pushed the brushes into the motor contacts were completely rusted into globs, along with the motor guide that is supposed to allow the motor to spin inside the case, being totally rusted to the motor. I took them all apart, completely apart, replaced the springs, cleaned out all the rust, cleaned and lubricated everything that was supposed to move (some parts were so bad I had to use high-grit sandpaper to get them reasonably smooth), lubricated the worm screws, put it back together, said a prayer to the seat motor gods, re-activated the airbag system, re-calibrated - et voila! Wouldn't you know it, the damned things worked. It took a couple re-calibrations to work through some of the grit and such to get the full travel, but eventually the full range was available and consistent. On one of the seats, one of the motors initially didn't work, so in frustration, I spammed the seat control up-down-up-down-up-down for probably 15 seconds, which miraculously loosened something up, and it began working, and hasn't stopped since.

I apologize, I thought I had taken more pictures when documenting, but looking back it wasn't that many; probably because my gloves were covered in rust and grease for most of the endeavor. I tried to annotate the pictures as well as I could after-the-fact, but let me know if I can clear anything else up. I still have the extra seat frame, and a couple extra motors, so if you need parts, or more pictures with explanation, maybe I can help.

OK; now that the story is out of the way, on to the repair with pictures.

====================

!!! IMPORTANT: !!!

====================

First, follow the repair manual with regard to de-powering / activating the airbag system, and how to remove the seats.

NOTE:

Go slow and take your time. Label things if you want. Do one motor at a time if you want. Don't rush it, getting frustrated will make it harder.

NOTE:

There are steel cables that go through the ends of the motors, and go into the gearboxes. They have square tips, but are mostly round. The square tip goes into the square receiver on the motor shaft. And one long cable through the torque tube attached to the horizontal motor. The torque tube rotates and will come off, but it's awkward.. you'll see.. The cables pull straight out of the motor shafts, and can be tricky to fit back into place sometimes. See next note...

NOTE:

The torque tube on the horizontal motor is a bitch. Seemed to be much harder to put back in than it was to take apart. Let's just say I had to bend it way more than I thought when trying to get it back in place. I really thought it was going to snap multiple times, or that I wasn't going to be able to put it back together. Just keep futzing with it, but be cautious at the same time, and don't snap it.

NOTE:

The steel cables that connect the motors to the gearboxes just pull straight out. Same thing with the one in the torque tube, it's just much longer. And a huge pain.

---------------------------------------------------

Tools:

---------------------------------------------------

Basic hand tools, screw drivers, pliers, etc. of various sizes

Torx T25 (gearboxes)

Small springs - the cheap assortment package from Lowes has some of about the right size, plus then you'll have like 50 extra springs to keep around. But I'm sure you can get some individually, sourced retail or from other things you have laying around.

Lubricant (I used white lithium mostly)

Brush for removing rust (I used a small brass brush)

Possibly some high-grit sandpaper, and/or fine steel wool

You will probably need a small ratcheting 90* screwdriver, (or bits for a 1/4 ratchet), for trying to get a screw into or out of the motor cases - very little clearance, and sometimes you're doing it by feel, which is made worse by the fact the motor magnets are pulling the screw out of alignment while you're also trying to hold all the pieces of the motor together...

---------------------------------------------------

1) Bottom-view of the driver's seat:

---------------------------------------------------

---------------------------------------------------

2) Removing the gear assembly from motor:

---------------------------------------------------

First, remove the electrical connectors from the motors. Then remove the motor from the gearbox assembly.

I found the best/only? way to get to the back of the motors so you can take them out, is to first remove the screws (T25) from the gearboxes first, then you can slide it up off the worm gear, and be able to rotate the motor so you can actually get at the screws on the back of it.

You may or may not be able/have to remove the rotations sensors at this step as well, I don't remember; Just be careful, they are totally plastic. You can see in the next pictures how they rotate, un-clip, and then just pull off of the square cable that goes into the motor.

^ Notice there is one screw for the aft vertical motor still in the mount - I think this one physically did not have enough clearance to be pulled out completely...

---------------------------------------------------

3) Motor disassembly

---------------------------------------------------

Once a motors is out, you can pull the case off (it's magnetic, and will get attracted to the motor, but it comes off). Then you might see something like this...

Yea that's not what it's supposed to look like.

---------------------------------------------------

3) Motor cleaning

---------------------------------------------------

NOTE:

Brushes are being pushed into the motor contact with springs. Be careful they don't fly out when you remove the motor.

NOTE:

There are braided wires going to the brushes. The brushes are supposed to slide in their slots to keep pressing against the copper contacts - as they get used and the brushes are worn, they continue to make contact.

Even as bad as these were, I didn't have to re-solder the braid, but be careful or you might.

I wish I took more pictures for these steps, sorry - maybe I can upload some after-the-fact.

What you will do here, is pull the motor out of the plastic mount. It should just pull straight out. Just be mindful that the springs don't go flying if the aren't held in by gunk, or whatever tab or item they were supposed to be attached held in with in the first place.

Once the motor is out, then you can slide the brushes out of their slots, clean the slots, clean the brush, replace a spring, etc.

I had to replace a spring on each of mine; I happen to have packages or misc sized springs that worked out well, but you may have luck even with a spring from a pen, and can cut it if you need to. Just try to match or get close to one of the good ones in size and compression.

Then, you should clean the metal inserts that are inside each end of the motor case, and make sure they are smooth inside. Also clean the motor shaft that rotates inside of this piece. Should look something like this when you're done:

---------------------------------------------------

4) Reassembly

---------------------------------------------------

Once everything is clean, you can start to put everything back together. Essentially reversing the steps you took when taking it apart.

NOTE:

Make sure to line the motor case up correctly, with the notches. It will be awkward to get the screws back in, as they will be attracted to the magnets in the case. Just keep fiddling with it until it goes in right.

Once all the motors are assembled (easier said than done, I know, again, sorry for the lack of pictures), then put the gearboxes back together, and the electrical connections back on the motors.

Follow the service manual for replacing the seat, and re-powering/activating the SRS system.

Don't be discourages if they don't immediately work; I had to run a few calibrations, and kinda work the seat controls a few times before they all worked. But then again, the corrosion I experienced will probably be worse than yours, the car was sitting for a little while with a leaky moon-roof before I got it.

That should be it, and if you're like me, you can now do the whole thing over again with the other seat! Much easier the second time around, after you figured out how things move around and go together.

Good luck, and let me know if there is anything I can explain in more detail.

Last edited: