You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

5R55 Repairs

- Thread starter mikeyswood

- Start date

mikeyswood

Active LVC Member

Update: A few thousand miles since the fix and this thing runs like a scalded dog.

When you get on the gas it throws you back in your seat and shifts perfectly through 120!

When you get on the gas it throws you back in your seat and shifts perfectly through 120!

alexfranke

Active LVC Member

You were right on the ball with the price the shop told me about $1850 for the rebuild.....He did show me the updated parts for the trans....just like in the post everything ford skipped on...

Is "the shop" the dealer? I mean, is a dealer shop typically just going to stick to a by-the-book repair/replace, or will they know not to use "crappy Mercon V" etc? Is this the type of thing I should take to a local transmission or general repair shop instead?

I'm getting delay from P to D/R, a little clunk from 1-2, and feels like some slop from 2-3.

Thanks!

mikeyswood

Active LVC Member

There are some dealers that know about the servo fix. The Mercon V that they use now properly lubricates the servo. Original Mercon V was the issue.

Shops and dealers may want to quote a full rebuild. If they do that take two steps back and the - with loud enough voice - laugh in their face because their ineptitude is hilarious.

Ask your shop if they are able to do the proper repairs. With this thread anyone can do it

Shops and dealers may want to quote a full rebuild. If they do that take two steps back and the - with loud enough voice - laugh in their face because their ineptitude is hilarious.

Ask your shop if they are able to do the proper repairs. With this thread anyone can do it

Is the P to D/R delay being described here accompanied by a bit of a hard engagement and 'squat' in the stance and a (for lack of a better description) or could this be just worn suspension components.

Also noticed that the shift points seem sloppy and tend to 'float' for a while before switching to the next gear. Would disconnecting the battery for a bit allow the shift points to be relearned on these cars ('02 LS V8)

Great write up, just hope I don't have to put it to use yet

Also noticed that the shift points seem sloppy and tend to 'float' for a while before switching to the next gear. Would disconnecting the battery for a bit allow the shift points to be relearned on these cars ('02 LS V8)

Great write up, just hope I don't have to put it to use yet

mikeyswood

Active LVC Member

Yes. The solenoid's piston is stuck in one position until enough force builds behind it and then it's thrown into the next position.

How do you accurately define "squat" over the internet? The momentum of the force varies by how badly your solenoid seals are gunked up. There could be worn suspension parts. Shocks should only be good for 80kish. How recently have you replaced them?

The battery reset may help. If you have not replaced your fluid 100% and the solenoid then I am able to say with 100% certainty that your shift issues are 95% due to your solenoid.

How do you accurately define "squat" over the internet? The momentum of the force varies by how badly your solenoid seals are gunked up. There could be worn suspension parts. Shocks should only be good for 80kish. How recently have you replaced them?

The battery reset may help. If you have not replaced your fluid 100% and the solenoid then I am able to say with 100% certainty that your shift issues are 95% due to your solenoid.

Just putting your foot on the break and shifting from neutral to drive will cause the rear-end to load up and the car to 'squat'. If you power break it will feel like someone pushing down on the rear. So the rear of the car squatting is normal to me. Unless shifting into gear at idle feels like the rear drops 4" then I wouldn't worry about that part.

hippiekiller

New LVC Member

This is a fantastic write up. Better than some I've already seen. I'm mechanically inclined enough where I would feel comfortable doing most of this on my own. Just a few things I'm kinda unsure about.

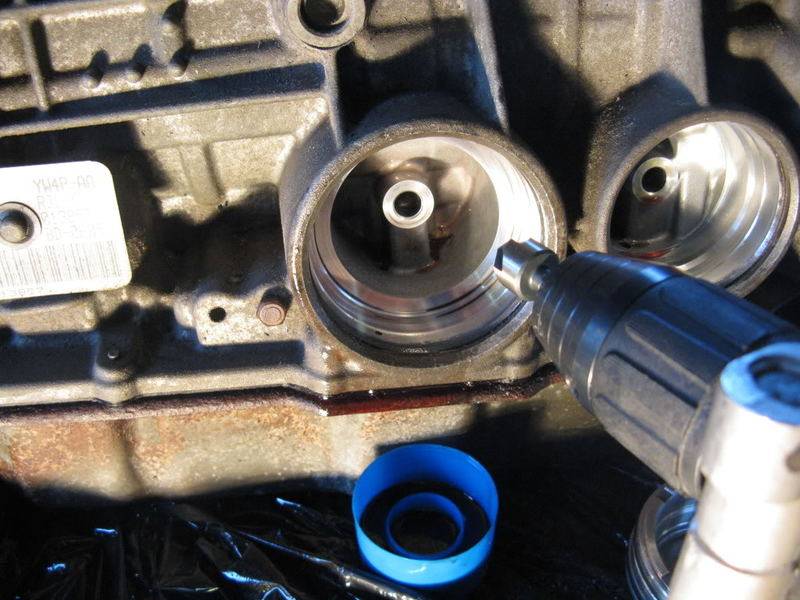

1. What would you call that bit you have on the drill to make the camfer? And how deep did you have to go? I wouldn't want to go too far.

2. I am going to attempt to do this with the transmission in the car so as I understand, that increases my risk of dropping my balls . Is there any way where I can find out where to put them back into just incase?

. Is there any way where I can find out where to put them back into just incase?

And one more thing.. Do you see any issue with doing the servos now and then the solenoids a few months later. I will want to do it all but right now I primarily have issues with harsh shifts, mainly between 2-3. And I'm in the Army (not exactly the highest paying job).

1. What would you call that bit you have on the drill to make the camfer? And how deep did you have to go? I wouldn't want to go too far.

2. I am going to attempt to do this with the transmission in the car so as I understand, that increases my risk of dropping my balls

And one more thing.. Do you see any issue with doing the servos now and then the solenoids a few months later. I will want to do it all but right now I primarily have issues with harsh shifts, mainly between 2-3. And I'm in the Army (not exactly the highest paying job).

mikeyswood

Active LVC Member

1. That's a countersink bit. You want .030" relief and you want something in the 80° range.

2. I would hate to hear of any man dropping his balls. Good luck doing it in the car; it's well worth the removal. Your clutch spring will fall out and also the rubber valve on top of it. It's in one of the pictures on the first page.

3. Yes. $100. You have to drain fluid to do the servos. It's financially smarter to do it all at once. There's no need to waste $7/qt.

2. I would hate to hear of any man dropping his balls. Good luck doing it in the car; it's well worth the removal. Your clutch spring will fall out and also the rubber valve on top of it. It's in one of the pictures on the first page.

3. Yes. $100. You have to drain fluid to do the servos. It's financially smarter to do it all at once. There's no need to waste $7/qt.

hippiekiller

New LVC Member

Thanks so much for the quick reply. To get the .030" relief, is there a tool of some sort or are you guesstimating? I haven't seen a micrometer that can measure something like that.

I've never dropped a transmission before. Ripped apart top sides of motors but never touched that. How long of a job is it and are there any special tools? Thanks again.

I've never dropped a transmission before. Ripped apart top sides of motors but never touched that. How long of a job is it and are there any special tools? Thanks again.

mikeyswood

Active LVC Member

You'll need some frinkin' huge extensions. That's about it.

I eyeballed the .030". You're creating a seating channel for the viton rings to sit on the pistons.

I could do this job in about four hours now; with no complications. You should plan a full weekend. The exhaust will cause problems.

I eyeballed the .030". You're creating a seating channel for the viton rings to sit on the pistons.

I could do this job in about four hours now; with no complications. You should plan a full weekend. The exhaust will cause problems.

trickett90

Well-Known LVC Member

I am now purchasing the parts to do this. I went to the ford servo bore fix website and this is what I found on the first page:

I am assuming it is no longer necessary to do this step:

Please confirm mikey.

The new assembly sleeves are in and will be installed on all units being shipped from 4-13-12 and on. No need to do the chamfer on the bores anymore. Also, this allows for doing the job by removing the upper and lower heat shields only which makes it possible to do the work in two hours or less as long as you have the right 90 degree needle nose pliers which we sell. The cost for the sleeves has been absorbed in the current price of the kits. See the what's new pager for more information.

I am assuming it is no longer necessary to do this step:

Please confirm mikey.

RigsLS

Dedicated LVC Member

- Joined

- Mar 10, 2012

- Messages

- 7,734

- Reaction score

- 523

[video=youtube;BW8eUe5VzOw]http://www.youtube.com/watch?v=BW8eUe5VzOw[/video]

5R55W/S/N/E Servo Bore Transmission Fix

http://www.fordservoboretransmissionfixsolution.com/index.html

http://www.fordservoboretransmissionfixsolution.com/symptoms--solution.html

5R55W/S/N/E Servo Bore Transmission Fix

http://www.fordservoboretransmissionfixsolution.com/index.html

http://www.fordservoboretransmissionfixsolution.com/symptoms--solution.html

JoeRanchero

New LVC Member

Yes Mikey, please confirm what trickket90 wrote in post #62. The reason I am asking is that I purchased and had installed Andrews servo bore kit for both servos and now the trans is worse now that ever. High 3000 rpm revs from 1-2 after driving for 2 miles, "E" display on instrument panel, check engine light. I am thinking that the plastic sleeve that was there to collapse the O rings is now either stuck in place or floating around. I don't blame the design of the modified kit, I'm just thinking something went wrong during the install and the only way to fix it is to pull the servos back out and bevel the bore face. I am assuming this will compress the O rings during the install.

Thank you Mikey.

Thank you Mikey.

mikeyswood

Active LVC Member

I'm not aware of the fix. I used the first revision and I'm going strong after 50k.

I do not think the rev issue you're seeing, Joe, is related to the servos. However, this is the internet and there are armies of people willing to tell me I'm wrong.

My first thought is the spring in the valve train broke on you. Is your trans shifting from first to second automatically?

I do not think the rev issue you're seeing, Joe, is related to the servos. However, this is the internet and there are armies of people willing to tell me I'm wrong.

My first thought is the spring in the valve train broke on you. Is your trans shifting from first to second automatically?

mikeyswood

Active LVC Member

Wow. That video is overkill. You just need to replace the servos. There's no reason to sleeve.

firemanls

Active LVC Member

So im pretty sure I need to replace my solenoid pack in my trans. So 2 questions:

1. Do I have to take the trans out of the car?

2. Is there anything else I need to do or look at while the pan is down?

Im not too savy with transmissions and Id hate to take it to the dealer or another mechanic and pay a arm and a leg for it.

1. Do I have to take the trans out of the car?

2. Is there anything else I need to do or look at while the pan is down?

Im not too savy with transmissions and Id hate to take it to the dealer or another mechanic and pay a arm and a leg for it.

joegr

Dedicated LVC Member

So im pretty sure I need to replace my solenoid pack in my trans. So 2 questions:

1. Do I have to take the trans out of the car?

2. Is there anything else I need to do or look at while the pan is down?

Im not too savy with transmissions and Id hate to take it to the dealer or another mechanic and pay a arm and a leg for it.

1. No. Be sure to get the bolt out of the connector to the solenoid assembly before you remove the pan. (You can do it after, but if you can't get the bolt out, then it's a waste to remove the pan.)

2. The filter and anything else that is broken.*

*: If only you knew if anything else was broken...

firemanls

Active LVC Member

And maybe I missed it but, how do I get the fluid back in the trans pan? Guy at the dealership told me there was a special tool used to put fluid back in since there was no dipstick.

Bolt is located where?

1. No. Be sure to get the bolt out of the connector to the solenoid assembly before you remove the pan. (You can do it after, but if you can't get the bolt out, then

Bolt is located where?

joegr

Dedicated LVC Member

And maybe I missed it but, how do I get the fluid back in the trans pan? Guy at the dealership told me there was a special tool used to put fluid back in since there was no dipstick.

Bolt is located where?

Bolt is in the middle of the connector, which is sort of on top of the transmission. You'll probably have to modify a wrench to do it.

You'll have to pump the fluid in through the fill port on the side.

This is all covered on here several times now. Do a little searching. (If I knew the links off hand, I'd post them.)

Our 2004 Lincoln LS w/102,000 miles has shifting problems such as on occasion slams into 3rd gear or has long hesitation going into drive from reverse or reverse from drive, and also on occasion slips tremendously from 2nd or 3rd to the point of free revving to 3200 or 4000 rpm if you don't catch it then slamming into the next gear. will occasionally unhook the battery for a couple hours and it all goes away for about a week and then it starts the occasional stunts all over again. Could this be related to the fixes in this thread? Bought it with 79,000 miles in 6/13 and do not know any history. Thanks

Our 2004 Lincoln LS w/102,000 miles has shifting problems such as on occasion slams into 3rd gear or has long hesitation going into drive from reverse or reverse from drive, and also on occasion slips tremendously from 2nd or 3rd to the point of free revving to 3200 or 4000 rpm if you don't catch it then slamming into the next gear. Will occasionally unhook the battery for a couple hours and it all goes away for about a week and then it starts the occasional stunts all over again. Could this be related to the any of these repairs? We bought it in 6/13 with 79,000 miles and have no idea of any history. Thanks

oddball

Dedicated LVC Member

Yup. That's a short list of suspects.

Band apply servos

Solenoid pack

Bands are past their use life (somewhat unlikely at that mileage)

Band apply servos

Solenoid pack

Bands are past their use life (somewhat unlikely at that mileage)

Elemino

Dedicated LVC Member

I will be buying a remanufactured transmission from a shop near my house next month. He said he uses upgraded parts to build it and is giving it a 3 year 75,000 mile warranty. $2950 installed.