hite337

Hite Performance

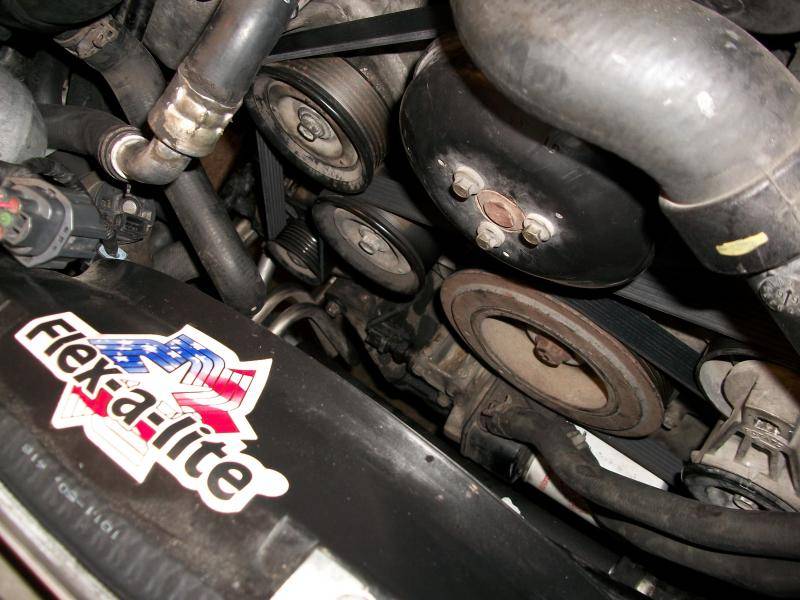

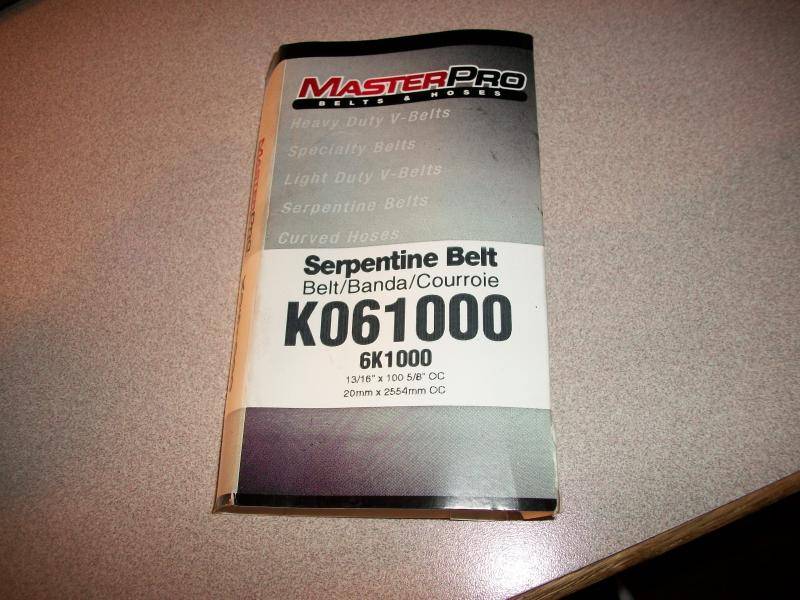

I replaced my hydraulic fan with a Flex-A-Lite 180 electric fan a few months back and I looped the hydraulic lines to the fan pump. This worked good for awhile but my fan pump began to whine a little. I searched this site for info on belt sizes for people who want to remove the fan pump and run a shorter belt. Alot of people asked this question and a clear answer was never posted. So here it is...a 13/16" x 100 5/8" belt with 6 ribs will fit.

I did the old string around the pulley trick and I bought 4 belts ranging from 98-101" and the 101" fit with the belt tensioner guage reading dead center. The fan pump was a SOB to remove but 5hrs of hell and it is history.

I also bought a different idler pulley for the top idler. It is identacle to the lower idler pulley with the flange on the outside. I wanted the flange because I didnt know if the belt would try to come off or not. It appears to ride well on the pulley so the stock pulley without the flange will probly work fine.

I did the old string around the pulley trick and I bought 4 belts ranging from 98-101" and the 101" fit with the belt tensioner guage reading dead center. The fan pump was a SOB to remove but 5hrs of hell and it is history.

I also bought a different idler pulley for the top idler. It is identacle to the lower idler pulley with the flange on the outside. I wanted the flange because I didnt know if the belt would try to come off or not. It appears to ride well on the pulley so the stock pulley without the flange will probly work fine.