Right on the Mark

Dedicated LVC Member

Ok I'm going to have to make a disclaimer here because this is my car and I work on it how I please. This write up does not imply that this is the only way to do this or the best way.Just way I did it. That said,on we go.

I hated putting the stock front brakes back on Red with the cast iron calipers. They also drag alot when trying to spin the wheels. I priced out Mustang drag brake setups and price was around 750 dollars that was a NO-GO. The non vented rotor kit also has max car weight of 3000 lbs so no way I could run that kit. The vented rotor kit I could run but 700+ dollars. I really just wanted alum calipers. Hmmm 2000 Mustang GT PBR's are alum. The GT rotor is also 10.9 dia compared to mk8 11.5.

I picked up these from local yard for 60 dollars. Big plus told him I need pads to come with them. They are Wagner Thermoquiets half life. Also he included lines because I needed the 3/8-24 banjo bolts that these calipers use. He would not sell me the used GT rotors. Bummer. But me being cheap went upstairs and found the original rotors I took off Red in 2007. They where like brand new. So not a penny spent on rotors. Here are the rotors being turned down to GT dia.

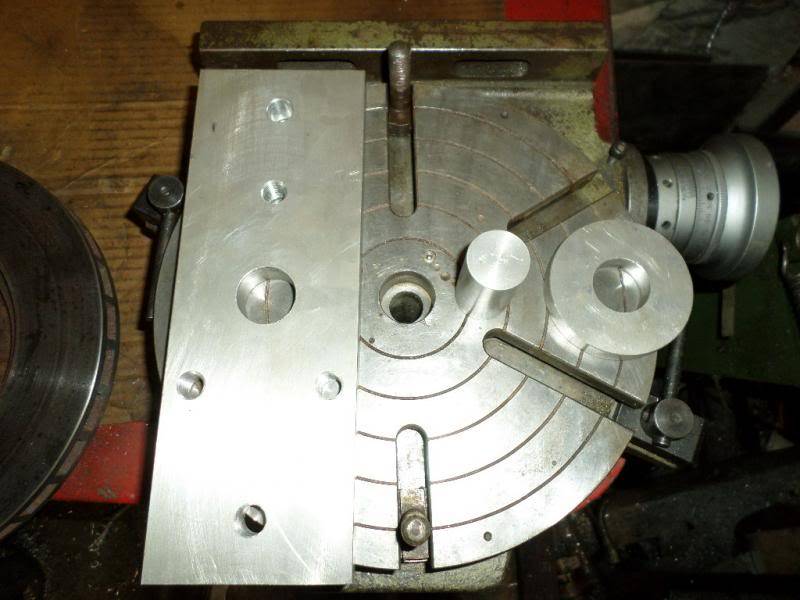

Now to get the rotors on the rotary table I had to make the 3 piece fixture. Here are all pieces laid out.

Here are all pieces bolted to rotary table.

The rotor vents didn't line up with the 0 on table so I had to insert bar and indicate the rotor vent with table on 0. Now clamp rotary table down.

All centerdrills.

All drilled

All mounted and looking good.

Everything worked mint at track no problems.

I hated putting the stock front brakes back on Red with the cast iron calipers. They also drag alot when trying to spin the wheels. I priced out Mustang drag brake setups and price was around 750 dollars that was a NO-GO. The non vented rotor kit also has max car weight of 3000 lbs so no way I could run that kit. The vented rotor kit I could run but 700+ dollars. I really just wanted alum calipers. Hmmm 2000 Mustang GT PBR's are alum. The GT rotor is also 10.9 dia compared to mk8 11.5.

I picked up these from local yard for 60 dollars. Big plus told him I need pads to come with them. They are Wagner Thermoquiets half life. Also he included lines because I needed the 3/8-24 banjo bolts that these calipers use. He would not sell me the used GT rotors. Bummer. But me being cheap went upstairs and found the original rotors I took off Red in 2007. They where like brand new. So not a penny spent on rotors. Here are the rotors being turned down to GT dia.

Now to get the rotors on the rotary table I had to make the 3 piece fixture. Here are all pieces laid out.

Here are all pieces bolted to rotary table.

The rotor vents didn't line up with the 0 on table so I had to insert bar and indicate the rotor vent with table on 0. Now clamp rotary table down.

All centerdrills.

All drilled

All mounted and looking good.

Everything worked mint at track no problems.