theophile

Well-Known LVC Member

2002 V8, completely stock. I got out of the car after arriving at work this morning and caught a faint smell of burning/melting rubber. They're blacktopping a new road nearby so I assumed it was that, but bent down to sniff where the hood meets the fender just in case. The smell was definitely coming from there so I popped the hood. There were some wisps of smoke coming from the right (driver) side of the engine compartment towards the back (firewall). I could not tell where the smoke was originating, but it was drifting up around the coolant bottle/brake reservoir area.

I turned the engine back on to watch/listen/smell, but everything seemed OK. I let it run for about a minute but didn't see the smoke return. I wasn't dressed for much more than that, so I haven't pulled off the cover or anything yet. But I do not see any fluid leaks and nothing is dripping from underneath. Also, the temp gauge is right at the middle, so it's not (apparently) overheating. No CEL.

The oil dipstick doesn't smell burnt, and other hydraulic fluids are at proper levels and do not appear to be contaminated. My first thought from the smell was rubber rather than burning fluid, so possibly a belt. The smell was also reminiscent of the smell my old '92 Escort produced the day or two before the clutch (manual transmission) finally stripped out.

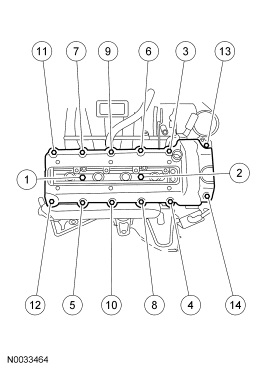

I am of course going to keep an eye on it, will check it when I get home, and will of course make time to get up into the engine bay to inspect properly. But in the meantime, I'd appreciate hearing any suggestions or ideas you might have as to possible things to check or pay special attention to. I've owned the car for about 5 months but have not yet really gotten up into the engine bay to learn it.

Thanks all!

I turned the engine back on to watch/listen/smell, but everything seemed OK. I let it run for about a minute but didn't see the smoke return. I wasn't dressed for much more than that, so I haven't pulled off the cover or anything yet. But I do not see any fluid leaks and nothing is dripping from underneath. Also, the temp gauge is right at the middle, so it's not (apparently) overheating. No CEL.

The oil dipstick doesn't smell burnt, and other hydraulic fluids are at proper levels and do not appear to be contaminated. My first thought from the smell was rubber rather than burning fluid, so possibly a belt. The smell was also reminiscent of the smell my old '92 Escort produced the day or two before the clutch (manual transmission) finally stripped out.

I am of course going to keep an eye on it, will check it when I get home, and will of course make time to get up into the engine bay to inspect properly. But in the meantime, I'd appreciate hearing any suggestions or ideas you might have as to possible things to check or pay special attention to. I've owned the car for about 5 months but have not yet really gotten up into the engine bay to learn it.

Thanks all!