ford nut

Local nut case

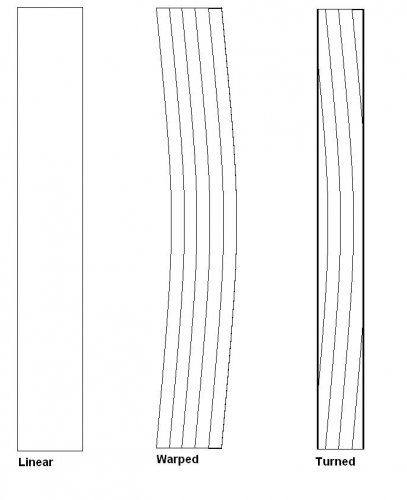

I agree. The linear runout will be removed. And the rotor may work just fine and never warp again. But the internal structure of the metal itself is still warped.

You lost me here.

I agree. The linear runout will be removed. And the rotor may work just fine and never warp again. But the internal structure of the metal itself is still warped.

You lost me here.

Its cast iron....

Thaywood i think you are somewhat right

Except that you dont know why the rotor warped

So the inside structure may actually be straight

If the metal warped from even heat you probably released

Tension already in the steel but either way the tolerance in cast iron is not very

tight i dont think you will ever notice a thickness difference of. 020-.030.

Why turn a rotor? There so cheap to buy new! I haven't turned a rotor since the 70's. Through them away and buy new!

Cause not everyone buys cheap

New 13" rotors for mine run around $240 for the pair.

Dam! My cheap 13" rotors are original tho. I guess if they ever go bad (which they probably won't if they haven't by now) I'll just buy some more cheap 13" and call it a day!

I don't see any reason to put bigger rotors and bakes on when it doesn't stop you any faster!

The more I think about it, the more trouble I have figuring out how a cast iron rotor can warp even with heat. I've never seen cast iron warp. When surface ground using coolant it is like mud coming off from it. Like sand.

I tend to not automatically accept things as true even when it has been said over and over. Warping cast iron just doesn't ring true to me. I could see how pad material could get stuck to the rotor in uneven distribution, causing brake pulse. That makes more sense to me.

Yes it does

I don't understand people who constantly break accelerate. People need to learn to coast.

To save money, material cost, rotors are cast thin now.

Resurfacing will not always give the desired results because of this.

They heat up fast and warp again..

It has little or nothing to do with the structure of the cast, unless you pay more from the start and buy a better cast rotor.

A turned rotor will be more inclined to warp again because of thickness and the disbursement of heat, not because the structure of the cast has changed.

How do you know this?? People do mods on there cars and take them to the track and come up with quicker times!

Is it the mods or the reaction time of the driver that do the justice?

How do you know it's the bigger brakes/rotors?

Not trying to start a argument, but...Is it the brakes/rotors that stop a car quicker or the reaction time of the driver?

I have newer cars/and stuff, that have bigger rotors/brakes then this car and this stops faster then any of them in my opinion (with stock)!

I just never had any problems stopping on a (dime) in this car with stock brakes/rotors!

Was just wondering because of the "pole mod" that happened to your car! You had bigger brakes/rotors didn't you? Why couldn't you stop in time with the bigger stuff? Was it the road conditions or driver error? How do you know the "stock" wouldn't have been better or the same?

The main question is....what proof is there? Bigger brakes/rotors or reaction time?